The gentle hum of an electric motor seamlessly blending with the roar of a gasoline engine, followed by a surge of instant, exhilarating power. This is the hallmark of modern hybrid electric vehicles (HEVs), often surprising drivers with their impressive acceleration, particularly from a standstill or during overtaking maneuvers. Far from being merely fuel-efficient compromises, many hybrids now offer a dynamic driving experience that rivals, and sometimes surpasses, their conventionally powered counterparts. But what is the secret behind this responsiveness? It is not solely the presence of an electric motor; rather, it is the profound and continuous evolution of battery technology that has truly unlocked the instant torque and rapid power delivery characteristic of today’s high-performing hybrids.

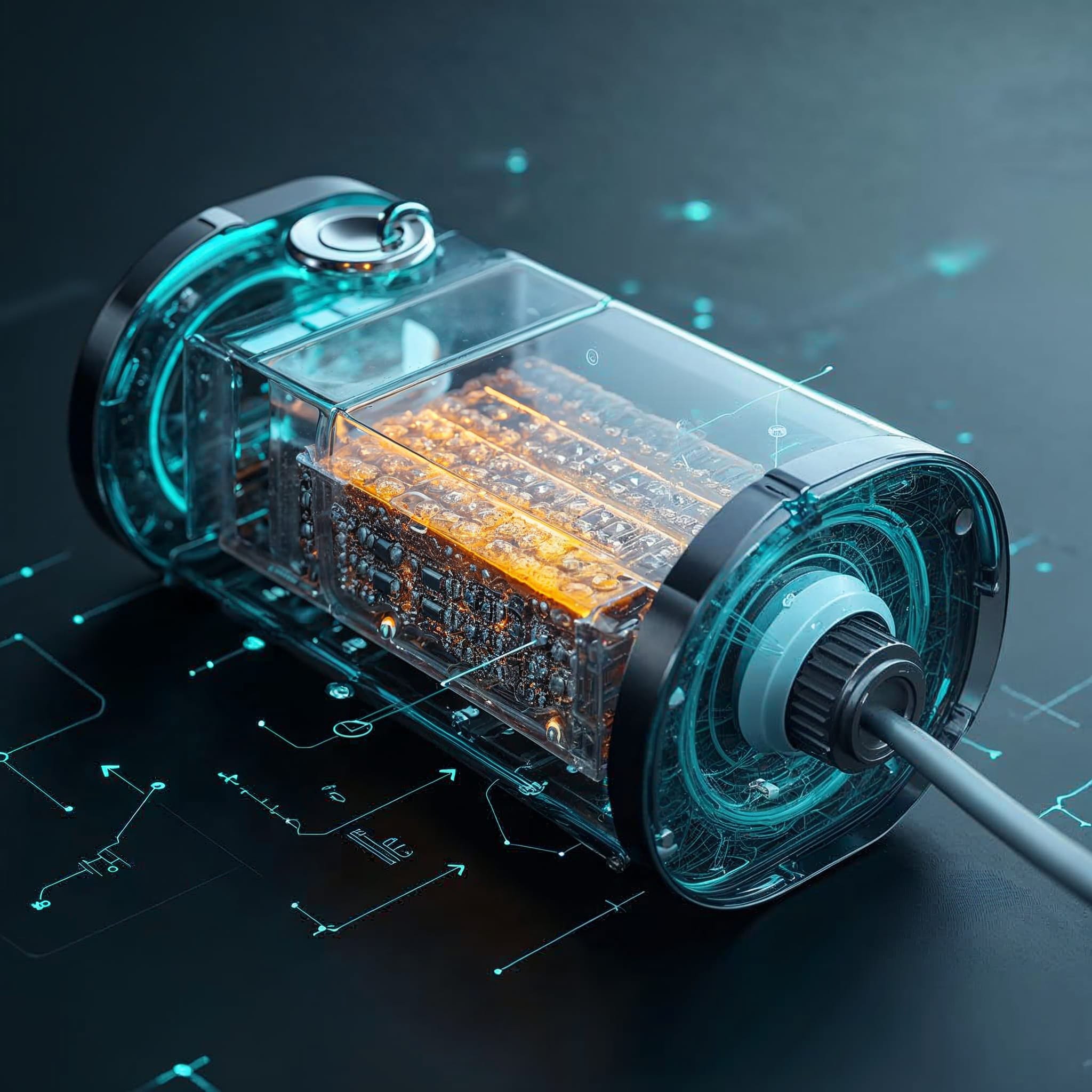

Underneath the hood, and indeed beneath the seats or in the trunk, lies a sophisticated energy storage system – the battery. This component has undergone a revolutionary transformation over the past few decades, evolving from rudimentary energy packs to highly advanced, finely tuned power units. These advancements are not just about storing more energy; they are critically about the battery’s ability to discharge a massive amount of electricity in a very short burst, precisely when the driver demands it. This article delves deep into the intricate relationship between battery development and hybrid vehicle acceleration, exploring the scientific principles, historical trajectory, and future innovations that continue to push the boundaries of what these intelligent machines can achieve.

We will uncover how different battery chemistries, sophisticated battery pack designs, and intelligent management systems work in concert to deliver that coveted instant response. From the pioneering days of Nickel-Metal Hydride (NiMH) to the current dominance of various Lithium-Ion (Li-ion) formulations and the promising horizon of solid-state batteries, each leap in battery technology has directly translated into palpable improvements in hybrid vehicle dynamics. Understanding this evolution is key to appreciating the subtle yet significant engineering marvels that power our increasingly electrified mobility.

The Electrified Advantage: Understanding Hybrid Vehicle Performance

At its core, a hybrid electric vehicle is a masterclass in compromise and synergy, combining the best attributes of both internal combustion engines (ICEs) and electric motors. Unlike a pure electric vehicle (EV) that relies solely on battery power, or a conventional car that burns only gasoline, hybrids blend these two power sources in various configurations to optimize fuel efficiency, reduce emissions, and, crucially for our discussion, enhance performance. The ‘instant response’ often associated with hybrids stems primarily from the electric motor’s unique power delivery characteristics.

Traditional gasoline engines, while powerful, suffer from inherent limitations regarding torque delivery. An ICE needs to rev up to a certain RPM (revolutions per minute) to generate its peak torque, leading to a slight but noticeable delay between pressing the accelerator and feeling the full thrust. This ‘lag’ is a consequence of mechanical inertia and the engine’s combustion cycle. In stark contrast, electric motors deliver maximum torque instantaneously from 0 RPM. This is a fundamental principle of electric propulsion: apply current, and the motor produces rotational force without needing to build up speed. This characteristic is precisely what gives hybrids their surprising alacrity, especially in urban stop-and-go traffic or when attempting a quick lane change.

When a driver demands rapid acceleration in a hybrid, the vehicle’s control system intelligently determines the optimal power split. In many cases, the electric motor kicks in immediately, providing that initial burst of torque to get the vehicle moving or to supplement the gasoline engine during a hard acceleration. This seamless integration means the electric motor can cover the momentary lag of the combustion engine, providing immediate forward momentum. The gasoline engine then smoothly takes over or works in conjunction with the electric motor to sustain higher speeds or more prolonged power demands.

Furthermore, regenerative braking plays a vital role in the overall performance cycle. When a hybrid vehicle decelerates, the electric motor acts as a generator, converting kinetic energy that would otherwise be lost as heat during friction braking into electricity. This electricity is then stored back in the battery, ready to be deployed again for the next acceleration event. This constant recapture and reuse of energy not only improves efficiency but also ensures the battery is frequently topped up, ready to provide those critical bursts of power. Without a battery capable of rapidly absorbing and discharging significant amounts of energy, this entire sophisticated dance between gasoline and electric power would be impossible. Thus, the battery is not just a storage unit; it is the critical component enabling the instant, dynamic interplay of a hybrid powertrain.

The Heart of the Hybrid: Battery Chemistry and Power Delivery

The battery is undeniably the heart of any hybrid vehicle, dictating not just its electric range but, more importantly for acceleration, its ability to deliver and accept power with incredible speed and efficiency. The performance of a hybrid battery is not simply about its total energy capacity (how far it can go on electric power), but crucially about its power density – its ability to deliver a large amount of power (watts) very quickly. High power density means the battery can push out a strong electrical current to the motor in an instant, translating directly into rapid acceleration.

Over the years, the automotive industry has leveraged various battery chemistries, each with its own set of advantages and limitations. The evolution from Nickel-Metal Hydride (NiMH) to various forms of Lithium-Ion (Li-ion) batteries marks a significant shift, directly influencing the dynamic capabilities of hybrids. While energy density is important for pure electric range, for hybrid acceleration, power density is paramount. It determines how quickly the electric motor can draw sufficient current to generate maximum torque.

A battery cell works by chemical reactions that create a flow of electrons from the negative electrode (anode) to the positive electrode (cathode) through an external circuit. For rapid discharge, these chemical reactions must occur quickly and efficiently, and the internal resistance of the battery must be low to allow a high current to flow without excessive heat generation or voltage drop. The specific materials used in the anode, cathode, and electrolyte dictate these characteristics. Early hybrid batteries were robust but relatively heavy and less power-dense. Modern Li-ion batteries, however, offer a superior combination of traits, enabling lighter battery packs that can unleash more power for longer durations.

Understanding these different chemistries and their impact on power delivery is crucial to grasping how battery development directly propels hybrid vehicle acceleration. Each iteration has brought improvements in power density, efficiency, thermal management, and overall durability, translating into more responsive, more capable hybrid vehicles. The journey of battery technology is a testament to continuous innovation in material science and electrochemical engineering, all in pursuit of that perfect, instantaneous electric push.

Nickel-Metal Hydride (NiMH) Batteries: The Early Pioneers

For decades, particularly from the late 1990s through the early 2010s, Nickel-Metal Hydride (NiMH) batteries were the undisputed workhorses of hybrid vehicle technology. Pioneered and popularized by models like the Toyota Prius, NiMH batteries proved to be a reliable and safe choice for the nascent hybrid market. Their robust nature, tolerance to a wide range of operating temperatures, and proven safety record made them an ideal fit for mass-market automotive applications where reliability and longevity were paramount concerns for consumer acceptance.

NiMH batteries operate on the principle of hydrogen absorption and desorption within a metal alloy electrode. During discharge, hydrogen stored in the metal hydride electrode reacts, releasing electrons, while at the positive electrode, nickel oxyhydroxide is reduced. This chemical process is highly reversible, allowing for thousands of charge-discharge cycles, which is critical for a hybrid vehicle that constantly cycles its battery through regenerative braking and power assistance. Their voltage per cell (around 1.2V) meant that a relatively large number of cells had to be linked in series to achieve the higher voltages required for automotive applications.

While NiMH batteries excel in terms of reliability and safety, they do come with certain limitations that eventually paved the way for newer chemistries. Their key drawbacks include a relatively lower energy density compared to modern alternatives, meaning they store less energy for their size and weight. This often resulted in heavier battery packs and less pure electric driving range, if any at all, for early hybrids. More pertinent to our discussion of acceleration, NiMH batteries also exhibit a lower power density compared to Li-ion. While they can deliver significant power, they tend to heat up more under high discharge rates and their internal resistance is higher, which limits the peak current they can sustainably deliver without significant voltage drop.

Despite these limitations, NiMH batteries were instrumental in establishing the viability and widespread adoption of hybrid vehicles. They provided a stable and effective platform for engineers to develop sophisticated hybrid control systems and electric motor technologies. However, as consumer expectations for performance and efficiency grew, and as battery technology rapidly advanced, the automotive industry began to look for more power-dense and energy-dense solutions to further enhance the driving experience, ushering in the era of lithium-ion batteries.

Lithium-Ion (Li-ion) Batteries: The Game Changer

The advent and refinement of Lithium-Ion (Li-ion) battery technology fundamentally revolutionized the hybrid vehicle landscape, acting as a genuine game-changer for performance and efficiency. Beginning in the late 2000s and accelerating into the 2010s, Li-ion batteries progressively replaced NiMH as the preferred energy storage solution for a vast majority of new hybrid models. This shift was driven by Li-ion’s superior electrochemical properties, which directly translated into enhanced vehicle dynamics, including significantly improved acceleration and overall responsiveness.

The primary advantage of Li-ion batteries lies in their vastly improved energy density and, critically for acceleration, their higher power density. This means that a Li-ion battery pack can store more energy in a smaller, lighter package, and critically, it can deliver a much larger burst of electrical current in an instant. The higher voltage per cell (typically 3.6-3.7V compared to NiMH’s 1.2V) also means fewer cells are needed to achieve the required system voltage, further contributing to a lighter and more compact battery pack. This reduction in weight directly benefits vehicle acceleration and handling, as the vehicle has less mass to move.

Li-ion batteries achieve their power through the movement of lithium ions between a graphite anode and a metal oxide cathode (e.g., lithium cobalt oxide, lithium manganese oxide, lithium nickel cobalt manganese oxide) through an electrolyte. The high mobility of lithium ions and the relatively low internal resistance of these systems allow for rapid charge and discharge rates. This translates directly into quicker power delivery to the electric motor, enabling more aggressive acceleration profiles and a more pronounced ‘electric boost’ when demanded by the driver.

Within the Li-ion family, there are several distinct chemistries, each optimized for different characteristics. For hybrid applications requiring high power and fast cycling, formulations like Lithium Nickel Manganese Cobalt Oxide (NMC) and Lithium Nickel Cobalt Aluminum Oxide (NCA) are common. These offer excellent power density and a good balance of energy density. Lithium Iron Phosphate (LFP) is also gaining traction, particularly in applications where extreme safety, longer cycle life, and lower cost are prioritized, though it typically has a slightly lower energy density compared to NMC/NCA. These specific chemistries are continually being refined to improve their ability to deliver sustained high power, manage heat efficiently, and extend battery life.

However, the integration of Li-ion batteries also presented new challenges, particularly concerning thermal management and safety. Early Li-ion cells could be susceptible to thermal runaway if not properly managed, leading to overheating. This necessitated the development of highly sophisticated Battery Management Systems (BMS) and advanced cooling strategies, which are now standard in all modern hybrid vehicles. Despite these engineering complexities, the performance benefits offered by Li-ion batteries have made them the undeniable standard for hybrid vehicle propulsion, enabling the instant, potent acceleration that modern drivers have come to expect.

Beyond Chemistry: Battery Pack Design and Management Systems

While the intrinsic chemistry of a battery cell dictates its fundamental capabilities, the transformation of individual cells into a fully functional, high-performance hybrid battery pack is an engineering feat of its own. It is in the intelligent design of the battery pack and the sophisticated algorithms of the Battery Management System (BMS) that the true potential of advanced battery chemistries is realized and optimized for instant power delivery and longevity. Without these crucial components, even the most advanced cells would be unable to provide the reliable, rapid acceleration demanded by modern hybrids.

Battery Pack Architecture: A modern hybrid battery pack is far more than just a collection of cells. It is a complex, integrated system designed for safety, efficiency, and performance. Cells are grouped into modules, which are then assembled into a larger pack. This architecture includes robust casings to protect against physical damage, internal wiring designed for high current flow with minimal resistance, and critical thermal management components. For rapid acceleration, the internal resistance of the entire pack must be minimized to allow for massive current flow without significant voltage drop or excessive heat generation. Engineers meticulously design the electrical pathways to ensure uniform current distribution and minimal energy losses.

Thermal Management: Delivering instant power generates significant heat within the battery pack. Excessive heat can degrade battery performance, shorten its lifespan, and in extreme cases, pose safety risks. Therefore, sophisticated thermal management systems are indispensable for maintaining the battery within its optimal operating temperature range. These systems can range from passive air cooling in less demanding applications to active liquid cooling systems, which circulate a coolant (often a glycol-water mixture) through channels integrated into the battery modules. Liquid cooling is particularly effective for high-performance hybrids, allowing the battery to sustain high power output for longer periods and recover more quickly from intense discharge cycles. This directly contributes to consistent acceleration performance, even under demanding driving conditions.

The Battery Management System (BMS): This is arguably the brain of the battery pack, a highly sophisticated electronic control unit that continuously monitors and manages every aspect of the battery’s operation. For instant acceleration, the BMS plays a critical role in several ways:

- Cell Balancing: It ensures that all individual cells within the pack are charged and discharged uniformly. Imbalances can limit the pack’s overall capacity and power output, as the weakest cell would dictate the performance of the entire pack.

- State of Charge (SoC) and State of Health (SoH) Monitoring: The BMS accurately estimates how much charge remains (SoC) and the overall health and degradation of the battery (SoH). This information allows the hybrid control system to make informed decisions about when to use electric power for acceleration and how much power can safely be drawn.

- Voltage and Current Regulation: During sudden acceleration demands, the BMS carefully regulates the current draw from the battery to prevent overcurrent, which could damage cells. Simultaneously, it ensures that sufficient voltage is supplied to the electric motor for maximum torque.

- Thermal Control Integration: The BMS actively manages the thermal management system, activating pumps or fans as needed to cool or, in some cold climates, even warm the battery to its optimal operating temperature, thus ensuring peak performance regardless of external conditions.

- Safety Protocols: Crucially, the BMS implements safety protocols to prevent overcharging, over-discharging, and overheating, mitigating risks and ensuring the long-term reliability of the battery pack, even during high-power bursts.

In essence, the synergy between advanced battery chemistry, meticulous pack design, and an intelligent BMS is what enables hybrid vehicles to deliver that seamless, potent, and instantly available acceleration. It is a testament to the intricate engineering required to harness immense electrical power safely and effectively within a compact automotive package.

Supercapacitors and Solid-State Batteries: The Future Frontier

While Lithium-Ion batteries currently dominate the hybrid landscape, the relentless pursuit of better performance, greater efficiency, and enhanced safety continues to drive research into next-generation energy storage technologies. Two areas holding significant promise for further propelling hybrid vehicle acceleration are supercapacitors and solid-state batteries, each offering distinct advantages and facing unique challenges on their path to widespread adoption.

Supercapacitors: Bridging the Power Gap

Supercapacitors, also known as ultracapacitors, are energy storage devices that sit somewhere between traditional capacitors and batteries. Their key advantage lies in their extraordinarily high power density and extremely rapid charge/discharge cycles. Unlike batteries, which store energy through chemical reactions, supercapacitors store energy electrostatically, by accumulating ions at the interface between electrodes and an electrolyte. This physical process is much faster and more efficient than chemical reactions, allowing supercapacitors to deliver massive bursts of power in milliseconds and absorb regenerative braking energy almost instantaneously.

For hybrid vehicles, this translates into several potential benefits for acceleration. Supercapacitors could augment or even partially replace batteries in specific high-power roles, such as providing initial launch acceleration or absorbing peak regenerative braking energy. Some high-performance hybrids and even Formula 1 KERS (Kinetic Energy Recovery System) have utilized supercapacitors to provide an instant, short-duration power boost. The primary limitation of supercapacitors, however, is their relatively low energy density. They cannot store nearly as much energy as batteries for their size and weight, meaning they are not suitable for providing sustained electric drive or significant electric range. Their role is often seen as a power enhancer, working in tandem with batteries, rather than a standalone solution.

Solid-State Batteries: The Next Revolution

Perhaps the most anticipated breakthrough in battery technology is the advent of solid-state batteries. These batteries replace the liquid or gel electrolyte found in conventional Li-ion batteries with a solid material. This seemingly simple change promises a cascade of benefits that could profoundly impact hybrid vehicle performance, particularly acceleration.

- Higher Energy Density: Solid-state batteries are projected to offer significantly higher energy density than current Li-ion batteries, potentially doubling or even tripling the amount of energy stored for the same volume and weight. While not directly about power, higher energy density means less weight for the same stored energy, which indirectly benefits acceleration. More importantly, it can enable a greater buffer of available power.

- Superior Power Density: With improved ion conductivity through solid electrolytes and better interfacial contact, solid-state batteries are expected to achieve even higher power densities than current Li-ion batteries. This would allow for even more rapid discharge rates, translating into a more potent and instantaneous surge of power to the electric motors for acceleration.

- Enhanced Safety: The elimination of flammable liquid electrolytes greatly reduces the risk of thermal runaway and fires, a significant safety advantage that could simplify battery pack design and allow for denser packaging.

- Faster Charging: Solid-state electrolytes can potentially support ultra-fast charging rates, minimizing downtime and increasing the availability of peak power.

- Longer Lifespan: Some solid-state chemistries show promise for extremely long cycle lives, which is beneficial for the demanding partial-cycling environment of hybrid vehicles.

While immensely promising, solid-state batteries are still largely in the research and development phase for mass automotive applications. Challenges include manufacturing scalability, achieving reliable performance across a wide range of temperatures, and ensuring long-term durability. Major automotive manufacturers like Toyota, Nissan, and Volkswagen, alongside numerous startups, are heavily investing in this technology, with some predicting commercial deployment in vehicles by the latter half of the 2020s or early 2030s. When fully realized, solid-state batteries are poised to elevate hybrid vehicle acceleration and efficiency to unprecedented levels, further blurring the lines between traditional hybrids and pure electric vehicles.

Impact on Driving Dynamics: From Commutes to Performance

The continuous advancements in battery technology have not merely been technical triumphs; they have had a profound and tangible impact on the real-world driving dynamics of hybrid vehicles, transforming the experience from mundane to genuinely engaging. This impact spans the entire spectrum of driving scenarios, from the daily urban commute to spirited highway cruising and even the realm of high-performance driving.

Urban Driving and Stop-and-Go Traffic: This is where the instant torque provided by the electric motor, powered by advanced batteries, truly shines. In typical city driving, characterized by frequent stops, starts, and low-speed maneuvering, traditional gasoline engines can feel sluggish. They require time to spool up to their optimal power band, leading to a noticeable delay. Hybrids, with their battery-fed electric motors, eliminate this lag. The moment the driver presses the accelerator, power is delivered instantly, resulting in a smooth, quiet, and brisk departure from a stop sign or traffic light. This instant responsiveness makes urban driving far less fatiguing and more enjoyable, as the vehicle feels light and agile, effortlessly keeping pace with traffic. Merging into gaps in traffic becomes less stressful, and the overall perception of the vehicle’s nimbleness is greatly enhanced.

Highway Overtaking and Merging: On highways, the immediate power surge from the electric motor, often combined with the gasoline engine, provides a significant safety and confidence advantage. When attempting to overtake another vehicle or merge onto a fast-moving freeway, rapid acceleration is crucial. Modern hybrid batteries, especially Li-ion variants, can discharge vast amounts of current to boost the electric motor’s output, allowing the vehicle to accelerate swiftly and decisively. This provides a compelling ‘passing power’ that can surprise drivers accustomed to the delayed response of conventional vehicles. The seamless integration means there is no discernible shift or hesitation; just a smooth, powerful push that makes highway maneuvers safer and more effortless.

Overall Driving Experience and Responsiveness: Beyond specific scenarios, the underlying improvement in battery power delivery elevates the entire driving experience. The car feels more connected to the driver’s inputs. There is a newfound precision in throttle response, as the electric motor fills in the power gaps of the gasoline engine. This directness contributes to a sense of control and confidence, making the vehicle feel more premium and technologically advanced. Drivers appreciate the quiet starts and low-speed electric-only driving, which further accentuates the feeling of refinement and sophistication that advanced battery technology enables.

Contribution to Fuel Efficiency: While primarily focusing on acceleration, it is important to note that the very same battery advancements that enable instant power also contribute significantly to improved fuel efficiency. By providing power instantly, the electric motor can allow the gasoline engine to operate more frequently in its most efficient RPM range or even shut off entirely during coasting, braking, or low-speed driving. The rapid charge acceptance of modern batteries means regenerative braking can recapture more energy more effectively, further reducing fuel consumption. Thus, the pursuit of better acceleration through battery development runs hand-in-hand with the goal of greater environmental sustainability, creating a win-win for both performance enthusiasts and eco-conscious drivers.

Comparison Tables

Table 1: Comparison of Hybrid Battery Chemistries

| Feature | Nickel-Metal Hydride (NiMH) | Lithium-Ion (Li-ion) | Solid-State (Future) |

|---|---|---|---|

| Power Density (Instant Power) | Moderate | High | Very High (Projected) |

| Energy Density (Stored Energy) | Low to Moderate | High | Very High (Projected) |

| Weight/Volume | Heavier, larger for given capacity | Lighter, more compact for given capacity | Potentially much lighter and smaller |

| Cycle Life | Good (Thousands of cycles) | Very Good (Thousands of cycles, depends on chemistry) | Excellent (Projected to be superior) |

| Cost | Lower | Moderate to High | Initially High, expected to decrease |

| Thermal Management | Less critical (Air cooling common) | More critical (Liquid cooling often required) | Potentially simpler due to enhanced safety |

| Safety | Excellent, highly stable | Very good (with robust BMS and cooling) | Potentially superior (no flammable liquid electrolyte) |

| Common Use in Hybrids | Early & current entry-level hybrids (e.g., older Prius) | Most modern and performance hybrids | Future premium & high-performance hybrids |

Table 2: Key Factors Influencing Hybrid Acceleration from Battery Perspective

| Factor | Impact on Acceleration | Explanation / Relevance |

|---|---|---|

| Battery Chemistry | Direct and significant | Li-ion (especially NMC/NCA) offers higher power density for faster current delivery compared to NiMH. |

| Battery Power Density | Direct and critical | Determines the maximum current a battery can supply quickly to the electric motor, translating to instant torque. |

| Battery Internal Resistance | Inverse correlation (lower is better) | Lower resistance allows higher current flow without significant voltage drop or heat generation, crucial for bursts of power. |

| Battery Management System (BMS) Efficiency | Crucial enabler | Optimizes cell balancing, monitors health, and ensures safe, consistent high-power discharge without degradation. |

| Thermal Management System | Enables sustained performance | Keeps battery within optimal temperature range, preventing power reduction due to overheating during rapid discharge. |

| Battery Pack Architecture | Supports optimal delivery | Efficient wiring, connections, and module design minimize internal losses and maximize power delivery to the motor. |

| State of Charge (SoC) Window | Affects available power | Hybrids typically operate batteries in a narrower SoC window (e.g., 40-80%) to maximize power availability and extend life. |

Practical Examples

Understanding the theoretical advancements is one thing, but witnessing their impact in real-world scenarios truly underscores the significance of battery development in hybrid vehicle acceleration. From mass-market pioneers to high-performance machines, the evolution of battery technology has redefined what drivers can expect from an electrified powertrain.

Case Study 1: The Evolution of the Toyota Prius

The Toyota Prius is arguably the most iconic hybrid, and its journey perfectly illustrates the impact of battery evolution. The first-generation Prius, launched in the late 1990s, relied entirely on Nickel-Metal Hydride (NiMH) batteries. While groundbreaking for its fuel efficiency, its acceleration was modest, often described as ‘adequate’ rather than exhilarating. Subsequent generations continued with NiMH, gradually improving performance through better integration and more powerful motors, but the fundamental battery limitations remained.

The turning point for the Prius began to appear around the third generation and fully materialized in the fourth and current fifth generations, which largely transitioned to Lithium-Ion (Li-ion) batteries (though some entry-level trims or markets still offer NiMH). The difference is palpable. Newer Prius models, particularly the Prime plug-in hybrid variants with larger Li-ion packs, offer noticeably snappier acceleration. The instant torque from the electric motor, powered by the more energy- and power-dense Li-ion battery, provides a much more responsive feel off the line and during mid-range acceleration. This allows the Prius to feel far more agile in traffic and capable on highways, showcasing how a change in battery chemistry can fundamentally alter the driving character of even a venerable model.

Case Study 2: Performance Hybrids – Lexus LC 500h and Honda NSX

To truly grasp the performance potential unlocked by advanced batteries, one must look at the top tier of hybrid engineering. Vehicles like the Lexus LC 500h (a luxury grand tourer) and the second-generation Honda NSX (a true supercar) leverage cutting-edge battery technology to achieve staggering acceleration figures and dynamic driving experiences.

- Lexus LC 500h: This vehicle utilizes a sophisticated Multi Stage Hybrid System featuring a powerful Li-ion battery. The battery’s high power density is crucial for delivering instantaneous electric assist, which works in conjunction with a V6 engine and a unique multi-stage transmission. The result is a seamless, relentless surge of power that propels the car with surprising urgency, giving it the immediacy of a much larger engine, but with hybrid efficiency. The battery’s ability to discharge and recharge rapidly is key to the system’s responsiveness, ensuring power is always on tap.

- Honda NSX: A technological tour-de-force, the NSX features a twin-turbo V6 engine paired with three electric motors – one integrated with the engine and two independently driving the front wheels. The crucial element here is a compact, high-output Li-ion battery pack. This battery is designed for extreme power delivery, allowing the electric motors to provide instant torque vectoring (directing power to individual wheels) and launch assistance. The immediate thrust from the electric components fills any turbo lag and provides an electrifying initial launch, contributing to its supercar-worthy 0-60 mph times. The battery’s high discharge rate is paramount for delivering the immense power required for such explosive acceleration and dynamic handling.

These examples demonstrate that when engineered for performance, advanced hybrid battery systems can enable vehicles to achieve acceleration figures and driving dynamics that were once the exclusive domain of large-displacement, conventional sports cars.

Case Study 3: The Urban Commuter’s Advantage

Beyond the realm of high-performance vehicles, the practical benefits of instant acceleration enabled by modern hybrid batteries are most acutely felt in daily urban commuting. Consider a driver navigating dense city traffic. The ability of a hybrid to accelerate quickly from a standstill means they can seize gaps in traffic more safely, merge into busy lanes with greater confidence, and experience less frustration during stop-and-go conditions. The vehicle feels lighter and more eager, making the otherwise monotonous task of commuting genuinely more pleasant.

Furthermore, this instant torque often allows the vehicle to operate in pure electric mode for longer periods at low speeds, or to launch purely on electric power before the gasoline engine seamlessly engages. This quiet, powerful launch enhances the feeling of refinement and sophistication, providing a smooth and effortless journey through the urban jungle. The advanced battery, therefore, isn’t just about speed; it’s about a superior, more responsive, and ultimately more enjoyable driving experience in the most common of scenarios.

Frequently Asked Questions

Q: What gives hybrid vehicles their instant acceleration?

A: The instant acceleration in hybrid vehicles primarily comes from their electric motors. Unlike gasoline engines, which need to rev up to generate peak torque, electric motors deliver maximum torque instantaneously from 0 RPM. This immediate power delivery, fueled by advanced batteries, allows hybrids to launch quickly from a standstill or provide a rapid boost during overtaking, seamlessly filling any power lag from the internal combustion engine.

Q: How do NiMH batteries compare to Li-ion in hybrids, especially for acceleration?

A: Nickel-Metal Hydride (NiMH) batteries, common in older hybrids, are reliable but have lower power density. This means they cannot deliver as much current as quickly, leading to more moderate acceleration. Lithium-Ion (Li-ion) batteries, used in most modern hybrids, offer significantly higher power density. They can discharge a much larger current in an instant, directly resulting in snappier, more potent acceleration and overall improved dynamic performance for the vehicle.

Q: What is the Battery Management System (BMS) and why is it important for acceleration?

A: The Battery Management System (BMS) is the electronic brain of the battery pack. It continuously monitors parameters like voltage, current, and temperature for every cell. For acceleration, the BMS is crucial because it ensures the battery can safely deliver maximum power by managing cell balancing, regulating current flow, and activating thermal management (cooling) to prevent overheating. Without an efficient BMS, a battery could not sustain high power output without damage or significant performance degradation.

Q: Can hybrid batteries deliver power indefinitely for acceleration?

A: No, hybrid batteries cannot deliver maximum power indefinitely. While they are designed for rapid discharge, sustained maximum power delivery would deplete the battery quickly and generate excessive heat. The BMS, along with the vehicle’s control unit, manages this to ensure optimal performance without overstressing the battery. Hybrids usually operate the battery within a specific State of Charge (SoC) window and cycle between electric and gasoline power to maintain both battery life and performance.

Q: How does regenerative braking relate to hybrid vehicle acceleration?

A: Regenerative braking is highly beneficial for acceleration. When a hybrid decelerates, the electric motor acts as a generator, converting kinetic energy into electricity and sending it back to the battery. This process recharges the battery, making sure there is always a sufficient charge available for the next acceleration demand. A battery with good charge acceptance can quickly store this recovered energy, ensuring the vehicle is always ready to provide instant electric boost.

Q: Are solid-state batteries currently used in hybrid vehicles?

A: As of the current date, solid-state batteries are not yet in widespread commercial use in hybrid vehicles. They are an emerging technology that is still largely in the research and development phase. While extremely promising due to their potential for higher energy/power density, improved safety, and faster charging, challenges in manufacturing, cost, and durability need to be overcome before they can be mass-produced for automotive applications. Some manufacturers anticipate their introduction in the late 2020s or early 2030s.

Q: Does battery weight affect hybrid acceleration?

A: Yes, battery weight definitely affects hybrid acceleration. A heavier battery pack means the vehicle has more mass to move, which requires more energy and reduces the overall acceleration performance, especially for a given power output. Advances in battery chemistry (like Li-ion over NiMH) have allowed for lighter, more compact packs that store more energy and deliver more power, thereby directly improving the power-to-weight ratio and enhancing acceleration.

Q: What are the main challenges in developing better hybrid batteries for acceleration?

A: Key challenges include: 1) Increasing power density further without sacrificing energy density, safety, or cycle life. 2) Improving thermal management to handle higher discharge rates and reduce degradation. 3) Reducing cost to make advanced batteries more accessible. 4) Developing sustainable and ethically sourced materials. 5) Enhancing reliability and durability to match the lifespan of a vehicle.

Q: How does temperature affect hybrid battery performance and acceleration?

A: Temperature significantly impacts battery performance. In very cold conditions, the chemical reactions inside the battery slow down, increasing internal resistance and reducing both power output (meaning slower acceleration) and energy capacity. In contrast, excessively hot temperatures can accelerate battery degradation and, if not managed by the BMS, can also reduce power output to prevent damage. Optimal thermal management is crucial to ensure consistent acceleration performance across different climates.

Q: Will hydrogen fuel cells replace batteries in hybrids for acceleration purposes?

A: Hydrogen fuel cells convert hydrogen gas into electricity, which then powers an electric motor, similar to a battery. While fuel cell electric vehicles (FCEVs) offer great range and quick refueling, they typically use a small buffer battery to handle sudden power demands for acceleration and to store regenerative braking energy. So, for the instant power bursts required for acceleration, a battery would still likely play a crucial role even in a fuel cell hybrid setup, rather than being completely replaced. Fuel cells are generally better suited for sustained power generation, while batteries excel at rapid power delivery and absorption.

Key Takeaways

- Hybrid vehicle acceleration, particularly its instant response, is primarily driven by the electric motor’s ability to deliver maximum torque from 0 RPM.

- Battery development is the critical enabler for this instant torque, with advancements in chemistry, pack design, and management systems.

- Nickel-Metal Hydride (NiMH) batteries were the reliable pioneers but offered lower power density.

- Lithium-Ion (Li-ion) batteries are the current game-changer, providing superior power and energy density, enabling significantly snappier acceleration and more compact packs.

- Sophisticated Battery Management Systems (BMS) and advanced thermal management are crucial for safely and efficiently delivering high bursts of power and ensuring battery longevity.

- Future technologies like supercapacitors and solid-state batteries promise even greater power density, safety, and efficiency, further enhancing hybrid performance.

- The impact of improved battery technology is felt across all driving scenarios, making urban commutes smoother and highway maneuvers safer and more confident.

- Instant acceleration from battery technology not only enhances performance but also contributes to overall fuel efficiency and a more refined driving experience.

Conclusion

The journey of hybrid vehicle technology is inextricably linked to the relentless innovation in battery development. What began as a nascent quest for fuel efficiency has evolved into a sophisticated dance between internal combustion and electric power, with the battery serving as the maestro orchestrating instant response and seamless transitions. From the dependable, albeit less dynamic, NiMH batteries of early models to the high-power, energy-dense Lithium-Ion chemistries that dominate today’s market, each leap forward has directly translated into more exhilarating acceleration, improved driving dynamics, and a more compelling overall vehicle experience.

The ‘instant response’ of a hybrid is not a mere byproduct; it is a meticulously engineered capability, made possible by batteries that can discharge immense electrical currents in milliseconds, supported by intelligent management systems that ensure safety and longevity. This capability transforms mundane commutes into engaging drives, empowers safer overtaking maneuvers, and fundamentally changes our perception of what a fuel-efficient vehicle can achieve in terms of performance.

As we look to the horizon, the promise of supercapacitors and, more profoundly, solid-state batteries hints at an even more electrifying future. These next-generation technologies threaten to push the boundaries of power density, energy storage, and safety even further, promising hybrids that are not only supremely efficient but also incredibly dynamic and responsive. The evolution of battery technology is far from over; it is a continuous revolution that will continue to propel hybrid vehicles forward, silently and powerfully, redefining mobility for generations to come. The silent surge of electrons, carefully controlled and rapidly delivered, remains the true heart of hybrid acceleration.