In an era where environmental consciousness and economic practicality intertwine, the quest for superior fuel efficiency in vehicles has never been more paramount. Hybrid electric vehicles (HEVs) stand as a pivotal bridge between conventional internal combustion engine (ICE) cars and fully electric vehicles (EVs), offering a compelling blend of range, power, and impressive fuel economy. At the very heart of a hybrid vehicle’s ability to achieve remarkable miles per gallon (MPG) figures lies its battery system. Far from being a mere power reservoir, the battery in a hybrid is a sophisticated component, continuously evolving and adapting to meet ever-increasing demands for efficiency, longevity, and performance. This comprehensive blog post will delve into the fascinating world of battery innovations that are propelling hybrid vehicle efficiency to new heights, exploring everything from fundamental battery types to advanced thermal management and futuristic chemistries.

Understanding the intricate relationship between battery technology and hybrid performance is crucial for appreciating the strides made in automotive engineering. We will uncover how groundbreaking developments in battery chemistry, structural design, and intelligent management systems contribute directly to the enhanced MPG ratings that make hybrids such an attractive option for consumers worldwide. Prepare to explore the past, present, and future of battery technology in the context of hybrid vehicles, revealing the ingenious solutions that empower these cars to go further on less fuel.

The Core Role of Batteries in Hybrid Efficiency

The battery is not just an auxiliary component in a hybrid vehicle; it is the central nervous system that orchestrates its fuel efficiency. Unlike traditional gasoline-powered cars, hybrids utilize an electric motor alongside a combustion engine, and the battery is the critical element that enables this dual-power dynamic. Its primary functions include storing electrical energy, providing power for the electric motor, and recapturing energy through regenerative braking. This multifaceted role directly impacts how much fuel a hybrid consumes.

One of the most significant contributions of the battery to MPG is its ability to facilitate electric-only driving at low speeds. In stop-and-go city traffic, where conventional gasoline cars are notoriously inefficient, hybrids can often operate purely on electric power, meaning zero fuel consumption during these segments. The battery powers the electric motor, moving the vehicle silently and efficiently. As speed increases or more power is demanded, the internal combustion engine seamlessly kicks in, working in conjunction with the electric motor or independently. This intelligent switching, largely enabled by the battery’s capacity to deliver and store energy rapidly, is a cornerstone of hybrid efficiency.

Furthermore, the battery acts as a crucial buffer for the internal combustion engine. During acceleration, the electric motor can provide an immediate torque boost, allowing the gasoline engine to operate in its most efficient RPM range or even assisting it to avoid excessive fuel consumption during peak power demands. This power assist capability ensures that the engine doesn’t have to work as hard, thus saving fuel. Without a robust and responsive battery, this synchronized operation would be impossible, leading to a much lower overall MPG. The rapid discharge and recharge cycles demanded by hybrid powertrains necessitate batteries that are not only energy-dense but also power-dense, capable of delivering and accepting significant currents almost instantaneously. This foundational understanding sets the stage for appreciating the subsequent technological advancements.

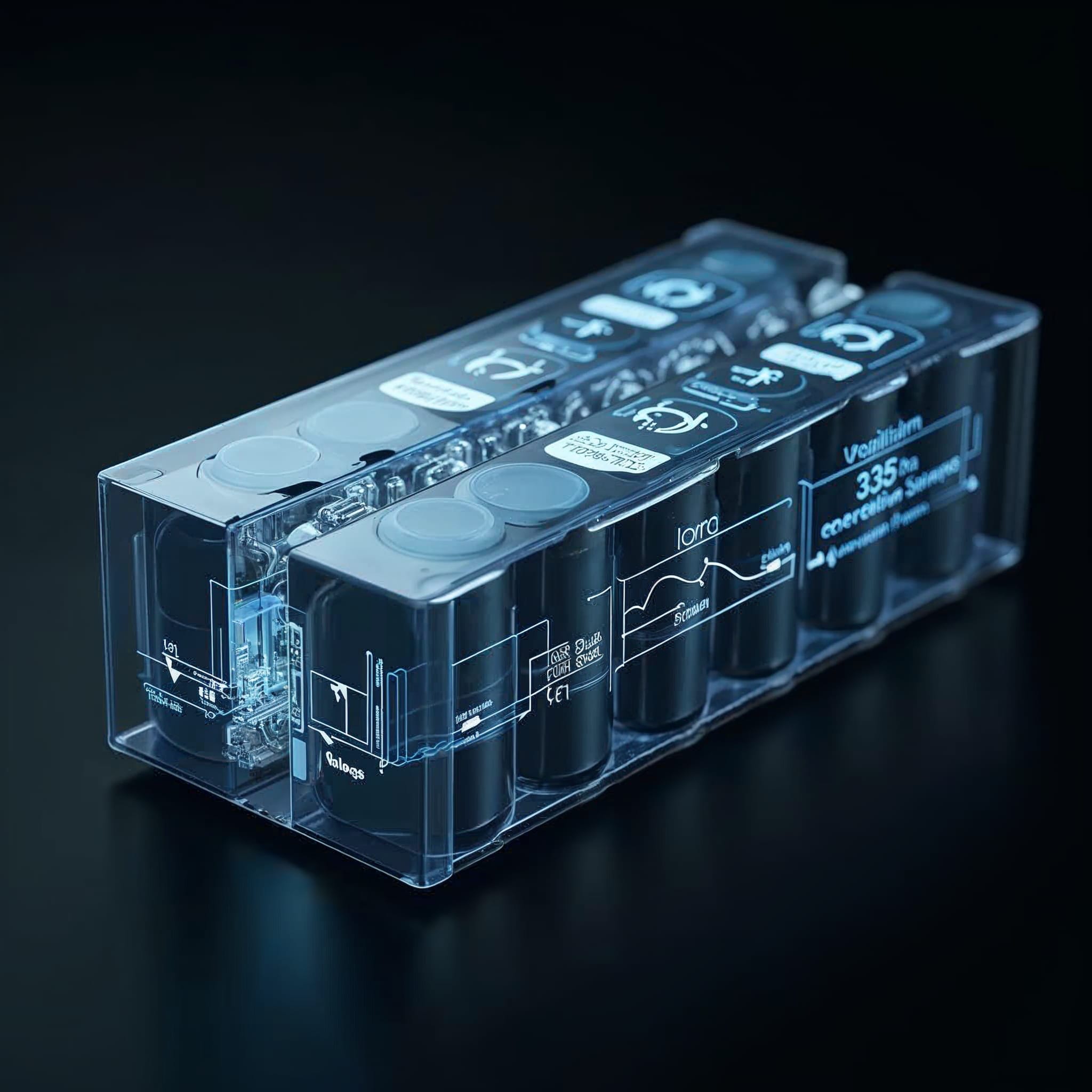

From NiMH to Li-ion: A Revolution in Energy Density

The evolution of battery technology in hybrid vehicles is a story of continuous improvement, driven primarily by the need for greater energy density, longer lifespan, and better overall performance. For many years, Nickel-Metal Hydride (NiMH) batteries were the undisputed champions in hybrid applications, powering iconic vehicles like the original Toyota Prius and Honda Insight. NiMH batteries offered a good balance of power, safety, and cost-effectiveness, proving their reliability over millions of miles. They were robust, relatively tolerant to abuse, and could handle the frequent charge and discharge cycles inherent in hybrid operation. However, NiMH technology had its limitations, primarily in terms of energy density and weight. These batteries were relatively bulky and heavy for the amount of energy they could store, which posed constraints on vehicle design and overall efficiency.

The advent and widespread adoption of Lithium-ion (Li-ion) batteries marked a significant paradigm shift in hybrid vehicle efficiency. Originally prominent in consumer electronics, Li-ion technology matured rapidly, offering several compelling advantages over NiMH. The most crucial benefit is its significantly higher energy density. This means Li-ion batteries can store more energy in a smaller and lighter package. For hybrid vehicles, this translates directly into several efficiency gains: a lighter vehicle requires less energy to move, improving fuel economy across the board. Furthermore, the increased energy storage capacity allows for longer durations of electric-only driving, particularly at higher speeds, and provides a more substantial power boost for the electric motor when needed. This extended electric-assist capability further reduces reliance on the gasoline engine, leading to higher MPG figures.

Beyond energy density, Li-ion batteries also boast a lower self-discharge rate, meaning they lose less charge when idle, and a higher power-to-weight ratio, enabling them to deliver more power more quickly. While the initial cost of Li-ion was higher and their thermal management requirements were more stringent, continuous advancements in chemistry, manufacturing processes, and battery management systems have made them the dominant choice for modern hybrids. The transition from NiMH to Li-ion was not merely an incremental upgrade; it was a fundamental shift that unlocked a new level of efficiency and performance for hybrid electric vehicles, truly revolutionizing what was possible in terms of fuel economy and driving experience. This shift underpins many of the most impressive MPG ratings seen in today’s hybrid market.

Advancements in Battery Chemistry for Hybrids

The term “Lithium-ion” is broad, encompassing a family of battery chemistries, each with distinct characteristics that car manufacturers leverage for specific hybrid applications. The continuous refinement of these chemistries is a key driver behind the ever-improving efficiency and performance of hybrid vehicles. Three prominent Li-ion chemistries commonly found in automotive applications are Nickel Manganese Cobalt (NMC), Lithium Iron Phosphate (LFP), and Nickel Cobalt Aluminum (NCA).

NMC batteries are widely used due to their excellent balance of high energy density, power capability, and a relatively long cycle life. They offer a good range for plug-in hybrids (PHEVs) and robust power delivery for full hybrids, making them versatile. Manufacturers carefully adjust the proportions of nickel, manganese, and cobalt to optimize for specific performance metrics, such as emphasizing nickel for higher energy density or manganese for improved thermal stability. These batteries allow hybrids to offer sustained electric-only driving and powerful acceleration, directly contributing to superior MPG figures by reducing the workload on the internal combustion engine.

LFP batteries, while typically having a slightly lower energy density compared to NMC, offer superior thermal stability, a longer calendar life, and are generally considered safer due to their resistance to thermal runaway. Their robustness and longevity make them an attractive option for certain hybrid applications where extreme durability is prioritized. The absence of cobalt, a contentious and often expensive material, also makes LFP a more cost-effective and ethically appealing choice. While they might not provide the absolute maximum electric range for a PHEV compared to an NMC equivalent, their stable performance and extended lifespan contribute to overall system reliability and sustained efficiency over the vehicle’s lifetime.

NCA batteries, primarily associated with Tesla but also used by other manufacturers, offer one of the highest energy densities among current Li-ion chemistries. This translates to maximum electric range for PHEVs and powerful performance. However, NCA batteries typically require more sophisticated thermal management systems due to their higher reactivity. The quest for higher energy density without compromising safety or lifespan is a continuous balancing act in battery research and development. The careful selection and optimization of these chemistries enable manufacturers to fine-tune the battery’s characteristics to match the specific demands of different hybrid models, from mild hybrids focused on regenerative braking to PHEVs designed for significant electric range.

Looking ahead, the horizon of battery chemistry is even more exciting. Research into solid-state batteries promises a revolutionary leap. These batteries replace the liquid electrolyte with a solid one, potentially offering even higher energy densities, faster charging capabilities, greatly enhanced safety (no flammable liquid electrolyte), and a longer lifespan. If successfully commercialized for automotive scale, solid-state batteries could redefine hybrid efficiency by allowing for smaller, lighter battery packs with greater storage capacity and faster recharge rates, further boosting electric-only range and reducing overall fuel consumption. Other advanced chemistries like lithium-sulfur and silicon anode batteries are also on the research roadmap, each holding the potential to unlock new levels of hybrid vehicle performance and MPG.

Thermal Management: The Unsung Hero of Battery Performance

While the chemical composition of a battery dictates its fundamental capabilities, how that battery is managed, particularly its temperature, profoundly impacts its real-world performance, lifespan, and ultimately, the hybrid vehicle’s MPG. Thermal management systems are the unsung heroes working behind the scenes to keep hybrid batteries operating within their optimal temperature range. Batteries are sensitive to temperature extremes; too hot, and they degrade rapidly, losing capacity and power; too cold, and their internal resistance increases, reducing power output and charging efficiency. Both scenarios directly translate to diminished fuel economy.

Early hybrid systems often relied on simpler air-cooling systems. These systems typically use fans to draw air from the cabin or outside the vehicle and circulate it around the battery pack. While cost-effective and relatively lightweight, air cooling is less effective at maintaining precise temperature control, especially in extreme ambient conditions or during periods of high demand (e.g., rapid acceleration or repeated regenerative braking). This can lead to the battery operating outside its ideal temperature window, reducing efficiency and accelerating degradation, which in turn can lower the vehicle’s overall MPG over time as the battery’s capacity diminishes.

Modern and more advanced hybrid vehicles, particularly plug-in hybrids with larger battery packs, increasingly employ sophisticated liquid-cooling systems. These systems circulate a coolant (often a mix of water and glycol) through channels or cold plates integrated within or around the battery modules. Liquid cooling offers significantly more precise and effective temperature regulation. It can dissipate heat more efficiently when the battery is working hard and can also warm the battery in cold climates, ensuring optimal performance regardless of external conditions. By maintaining the battery at its ideal operating temperature, liquid cooling maximizes its efficiency during both discharge and charge cycles, ensures consistent power delivery for the electric motor, and preserves its lifespan. A healthy, optimally functioning battery contributes maximally to regenerative braking efficiency and electric-only driving, directly translating to superior and sustained MPG throughout the vehicle’s life.

The sophistication of thermal management extends beyond just cooling or heating. Some advanced systems integrate with the vehicle’s air conditioning system to provide active cooling, while others utilize dedicated heat pumps for highly efficient temperature regulation. The goal is always the same: to ensure the battery can operate at peak performance for as long as possible. A battery that is too hot or too cold cannot accept charge as efficiently during regenerative braking, nor can it deliver power as effectively to the electric motor, resulting in more reliance on the gasoline engine. Therefore, effective thermal management is an indispensable innovation for maximizing and maintaining the high MPG figures that hybrid vehicles promise, representing a critical, albeit often invisible, component of their overall efficiency strategy.

Battery Management Systems (BMS) and Software Optimizations

Beneath the physical structure and thermal controls of a hybrid battery lies its digital brain: the Battery Management System (BMS). This sophisticated electronic system is absolutely critical for the safe, efficient, and long-lasting operation of any modern automotive battery pack, especially in hybrids where the battery undergoes frequent and dynamic charge/discharge cycles. The BMS is much more than a simple monitor; it is a complex orchestra conductor, ensuring every cell within the battery pack performs optimally, which directly translates to maximizing MPG.

The primary functions of a BMS include:

- Voltage and Current Monitoring: Continuously measures the voltage of individual cells or modules, as well as the overall pack current, to prevent overcharging or deep discharging, which can severely damage battery health.

- Temperature Monitoring: Tracks temperatures across various points within the battery pack to inform the thermal management system when cooling or heating is required.

- Cell Balancing: Ensures that all cells within the pack maintain a similar state of charge. Without balancing, some cells might degrade faster than others, limiting the overall pack capacity and lifespan. A balanced pack ensures maximum usable energy and power.

- State of Charge (SoC) and State of Health (SoH) Estimation: Provides accurate estimates of how much energy remains in the battery and its overall health/degradation level. This information is crucial for the vehicle’s powertrain control unit to make informed decisions about power delivery and regenerative braking.

- Fault Detection and Protection: Identifies and mitigates potential issues like short circuits, over-currents, or thermal runaway, enhancing safety and preventing catastrophic failures.

By meticulously performing these functions, the BMS ensures that the battery always operates within its safe and efficient parameters. This optimization means the battery can consistently accept charge from regenerative braking and deliver power to the electric motor at its peak efficiency, directly supporting the hybrid’s high MPG.

Beyond the core hardware protection, software optimizations within the BMS and the vehicle’s powertrain control unit play an equally vital role. These intelligent algorithms predict energy demands and availability, orchestrating the seamless interplay between the engine, electric motor, and battery for optimal fuel economy. For example, advanced control strategies might use GPS data and driving patterns to implement predictive energy management. If the system knows the car is approaching a downhill section, it might deplete the battery slightly more to maximize the amount of energy that can be recovered through regenerative braking on the descent. Conversely, if it anticipates a demanding uphill climb, it might ensure the battery has sufficient charge to assist the engine effectively.

Another crucial software optimization involves the strategic use of “sweet spots” for both the gasoline engine and the electric motor. The BMS, in conjunction with the vehicle’s control unit, constantly decides whether to use electric power, gasoline power, or a combination, based on instantaneous driving conditions, battery SoC, and driver input. It aims to run the gasoline engine in its most efficient RPM range whenever it is active, and similarly, to maximize the use of electric power during low-load conditions or when coasting. These sophisticated software algorithms are continuously refined by manufacturers, leveraging real-world driving data to squeeze every possible ounce of efficiency out of the hybrid powertrain, ultimately leading to impressive and ever-improving MPG figures. The intelligence embedded in the BMS and its accompanying software is just as significant as the physical battery itself in driving hybrid vehicle efficiency.

The Impact of Battery Size and Weight on Efficiency

In the pursuit of maximizing MPG, every gram of weight and every cubic centimeter of space in a vehicle matters. The battery, being one of the heaviest and most voluminous components in a hybrid powertrain (especially in plug-in hybrids), has a profound impact on the vehicle’s overall efficiency. For decades, automotive engineers have waged a relentless battle against weight, understanding that a lighter vehicle requires less energy to accelerate, maintain speed, and overcome inertia. This fundamental principle of physics directly applies to the design and integration of hybrid battery packs.

The advancements in battery chemistry, particularly the shift from NiMH to Li-ion, have been instrumental in this regard. As discussed earlier, Li-ion batteries offer a significantly higher energy density, meaning they can store more electrical energy per unit of mass and volume. This has allowed manufacturers to design smaller and lighter battery packs that deliver the same, or even greater, power and energy storage capacity than their older, heavier counterparts. A lighter battery directly contributes to improved MPG because the overall vehicle mass is reduced. For instance, shedding 100 kilograms from a vehicle can improve its fuel economy by a noticeable percentage, depending on the vehicle type and driving conditions. This reduction in weight isn’t just about the battery itself, but also the ancillary structures and components required to house and manage it.

Furthermore, the physical size of the battery pack affects vehicle design and aerodynamics. A more compact battery allows for better packaging, potentially freeing up interior space or enabling a more aerodynamic body shape, both of which can enhance fuel efficiency. The strategic placement of the battery also plays a role in optimizing the vehicle’s weight distribution, which can improve handling and stability, contributing to a better driving experience.

However, there’s a delicate balance to strike, especially with plug-in hybrid electric vehicles (PHEVs). PHEVs are designed to offer a significant electric-only range, which necessitates a larger battery pack compared to conventional full hybrids. While a larger battery provides more electric range (and thus potentially higher overall MPG if driven predominantly on electricity), it also adds considerable weight and cost. Manufacturers must carefully weigh the benefits of increased electric range against the penalty of added mass and its impact on the gasoline engine’s efficiency once the battery is depleted. This trade-off is often optimized through sophisticated energy management software that ensures the larger battery’s weight is justified by its utility.

The ongoing development of next-generation battery technologies, such as solid-state batteries, holds even greater promise for further reducing battery size and weight. If these technologies deliver on their promise of even higher energy density, future hybrid vehicles could feature battery packs that are dramatically smaller and lighter than current Li-ion packs, pushing MPG figures to unprecedented levels while potentially also reducing manufacturing costs and improving vehicle dynamics. The continuous drive to miniaturize and lighten battery systems is a core innovation strategy for maximizing hybrid vehicle efficiency, proving that sometimes, less truly is more when it comes to fuel consumption.

Regenerative Braking and Energy Recovery Systems

One of the most ingenious aspects of hybrid vehicle technology, and a primary contributor to their impressive MPG, is the implementation of regenerative braking. This system fundamentally alters how energy is handled during deceleration, turning what would typically be wasted kinetic energy into usable electrical energy that is stored in the battery. In a traditional gasoline car, when the driver lifts off the accelerator or presses the brake pedal, the vehicle’s kinetic energy is converted into heat through friction in the brakes, which is then dissipated into the atmosphere—a pure waste of energy.

In a hybrid, the electric motor acts as a generator during deceleration. When the driver brakes or coasts, the motor reverses its function, slowing the vehicle by converting its kinetic energy into electricity. This electricity is then sent back to the high-voltage battery pack, recharging it. The efficiency of this energy capture and storage process is directly dependent on the battery’s capability. A robust battery with good power density can accept a high rate of charge, meaning it can quickly and effectively store the energy generated during braking. This is particularly beneficial in city driving or stop-and-go traffic, where frequent braking allows for continuous replenishment of the battery, maximizing the opportunities for electric-only driving or electric assist. The more efficiently a battery can absorb and release this recovered energy, the greater the impact on the overall MPG.

The integration of regenerative braking is seamlessly managed by the vehicle’s control systems, often blending regenerative braking with traditional friction braking. At the initial stages of braking, the electric motor handles most of the deceleration, charging the battery. If more braking force is required, the conventional hydraulic brakes engage to supplement the electric braking. This blend is often imperceptible to the driver, providing a smooth and natural braking feel while maximizing energy recovery. The recovered energy can then be used to power the electric motor during subsequent acceleration, assist the engine, or enable electric-only driving segments, all of which reduce fuel consumption.

The efficiency gains from regenerative braking are substantial, particularly in urban environments where braking opportunities are plentiful. It is not uncommon for hybrids to achieve significantly better MPG in city driving compared to highway driving, a stark contrast to conventional gasoline vehicles. This is primarily due to the repeated cycles of energy recovery and deployment facilitated by the battery. Without advanced batteries capable of rapid charge acceptance and efficient energy storage, the full potential of regenerative braking could not be realized. Therefore, the innovations in battery technology—from high-power Li-ion chemistries to intelligent BMS that optimize charging rates—are intrinsically linked to the effectiveness of regenerative braking, making it a cornerstone of hybrid vehicle efficiency and a major driver of their superior MPG figures.

Future Outlook: Next-Gen Battery Technologies

The current advancements in Li-ion battery technology have propelled hybrid vehicle efficiency to impressive levels, but the research and development pipeline for even more revolutionary battery chemistries is vibrant. The automotive industry is constantly seeking the next big leap, aiming for batteries that offer higher energy density, faster charging times, enhanced safety, and even longer lifespans. These next-generation technologies hold the promise of further maximizing MPG in hybrids, potentially blurring the lines between hybrids and full EVs.

Perhaps the most talked-about future battery technology is the solid-state battery. As mentioned earlier, solid-state batteries replace the flammable liquid electrolyte found in current Li-ion batteries with a solid material. This fundamental change promises several transformative benefits:

- Higher Energy Density: Solid electrolytes can enable the use of lithium metal anodes, which have a much higher theoretical energy density than traditional graphite anodes. This means more energy can be packed into a smaller, lighter battery, leading to greater electric range for PHEVs and reduced weight penalties for all hybrids, directly boosting MPG.

- Improved Safety: Eliminating the flammable liquid electrolyte significantly reduces the risk of thermal runaway and fire, making solid-state batteries inherently safer.

- Faster Charging: Solid-state batteries are expected to handle much higher charging rates, meaning quicker turnaround times for PHEVs and greater efficiency in capturing regenerative braking energy.

- Longer Lifespan: The solid electrolyte can mitigate dendrite formation (lithium metal spikes that grow and short-circuit cells), leading to a longer cycle life and better retention of capacity over time.

While still facing manufacturing challenges related to scalability and cost, solid-state batteries are seen as the holy grail for automotive electrification, including advanced hybrids.

Beyond solid-state, other promising chemistries are under active investigation:

- Silicon Anode Batteries: Silicon has a theoretical capacity ten times greater than graphite. Incorporating silicon into anodes could significantly increase the energy density of current Li-ion batteries, enabling smaller, lighter packs with greater range and efficiency.

- Lithium-Sulfur (Li-S) Batteries: Sulfur is abundant and inexpensive, and Li-S batteries have a theoretical energy density significantly higher than current Li-ion batteries. However, challenges related to cycle life and stability need to be overcome.

- Sodium-ion (Na-ion) Batteries: Sodium is even more abundant than lithium, making Na-ion batteries potentially cheaper and more sustainable. While currently having a lower energy density than Li-ion, they are being explored for less demanding applications or as a complementary technology, particularly where cost and resource availability are paramount.

These emerging battery technologies, once mature, could further revolutionize hybrid efficiency by offering unprecedented energy storage capabilities, quicker energy replenishment, and potentially lower overall costs. For hybrids, this means even more extended electric-only driving, more powerful electric assist, and a lighter overall vehicle, all contributing to significantly higher MPG figures and a further reduction in carbon emissions. The continuous innovation in battery chemistry underscores the dynamic and exciting future of hybrid vehicle technology.

Comparison Tables

Table 1: Hybrid Battery Chemistry Comparison

| Feature | Nickel-Metal Hydride (NiMH) | Lithium-ion (Li-ion) (NMC/NCA) | Lithium-ion (Li-ion) (LFP) | Solid-State Battery (Future Potential) |

|---|---|---|---|---|

| Energy Density (Wh/kg) | 50-80 | 150-250+ | 90-140 | 400-500+ (Projected) |

| Power Density (W/kg) | 100-200 | 200-350+ | 150-250 | High (Projected) |

| Lifespan (Cycles) | 1,000-2,000 | 1,000-3,000 | 2,000-5,000+ | Significantly Higher (Projected) |

| Thermal Stability | Good | Moderate (requires BMS) | Excellent | Excellent (non-flammable electrolyte) |

| Cost per kWh | Moderate | Moderate-High (decreasing) | Low-Moderate | High (currently, projected to decrease) |

| Main Benefit for Hybrids | Reliability, established tech | High energy/power, less weight | Safety, longevity, cost-effective | Max energy, ultra-fast charging, safety |

| Typical Use Case | Older hybrids, some mild hybrids | Full hybrids, PHEVs (mainstream) | Cost-sensitive hybrids, longer-life applications | Future advanced hybrids, long-range PHEVs |

Table 2: Hybrid Battery System Components and their Impact on MPG

| Component | Primary Function | Direct Impact on MPG | Indirect Impact on MPG |

|---|---|---|---|

| Battery Cells (e.g., Li-ion) | Stores/delivers electrical energy | Enables electric-only driving, power assist, regenerative braking energy storage. Higher energy/power density means more efficient operation. | Reduced vehicle weight (due to smaller, lighter packs), allowing for more aerodynamic design and less energy needed to propel the vehicle. |

| Battery Management System (BMS) | Monitors, balances, protects cells; estimates SoC/SoH | Optimizes charge/discharge cycles, ensuring battery operates at peak efficiency for energy capture and delivery. Prevents degradation. | Extends battery lifespan, ensuring sustained efficiency over years. Allows for precise energy flow control, integrating engine/motor seamlessly. |

| Thermal Management System | Maintains optimal battery temperature | Ensures battery can accept and deliver power efficiently in all climates, maximizing regenerative braking and electric assist performance. | Prevents premature battery degradation, preserving capacity and power output over the vehicle’s lifetime, thus maintaining high MPG. |

| Inverter/Converter | Converts DC to AC for motor, AC to DC for battery | High efficiency conversion reduces energy loss, meaning more electric power is available for propulsion and less is wasted during charging. | Reliable power delivery for electric motor, allowing the engine to shut off more frequently or operate in its most efficient range. |

| Electric Motor/Generator | Propels vehicle, generates electricity during braking | Converts recovered kinetic energy into electricity for storage. Provides torque assist, allowing engine to run more efficiently or shut off. | Enables electric-only driving segments and enhances overall powertrain efficiency by optimizing engine load. |

Practical Examples of Battery Innovations Driving MPG

The theoretical advancements in battery technology translate into tangible benefits for everyday drivers through a multitude of hybrid vehicles on the market. These real-world applications showcase how different manufacturers leverage battery innovations to achieve impressive fuel efficiency figures.

Toyota Prius (Evolution of a Pioneer): The Toyota Prius is arguably the most recognizable hybrid, and its journey perfectly illustrates the evolution of hybrid battery technology. Early generations (like the 2nd Gen 2004-2009) famously used Nickel-Metal Hydride (NiMH) batteries. These batteries were reliable but relatively heavy and less energy-dense. Despite this, the Prius achieved groundbreaking MPG for its time, primarily due to Toyota’s robust hybrid synergy drive system and efficient engine. With later generations, particularly the 4th generation (2016-2022) and the current 5th generation (2023 onwards), Toyota shifted to Lithium-ion (Li-ion) batteries for many of its models and trims, including the Prime plug-in hybrid variants. The Li-ion batteries allowed for a smaller, lighter battery pack, leading to improved fuel economy, enhanced acceleration due to better power delivery, and crucially, a significantly longer electric-only range for the Prime models. This evolution directly contributed to the Prius’s continuous improvement in MPG, reaching figures well into the 50s for combined driving.

Hyundai Ioniq Hybrid (Li-ion from the Start): When the Hyundai Ioniq Hybrid was introduced, it made a statement by adopting a Lithium-ion Polymer battery (a variant of Li-ion) from its inception, unlike many competitors that transitioned from NiMH. This decision allowed the Ioniq to immediately benefit from the higher energy density and lighter weight of Li-ion, contributing to its class-leading fuel economy figures, often competitive with or exceeding the Prius. The compact nature of the Li-ion battery also facilitated a more spacious interior and a lower center of gravity, enhancing driving dynamics without sacrificing efficiency. The Ioniq’s integrated approach, where the Li-ion battery was a core design element rather than an upgrade, showcased how modern battery choices could be optimized from the ground up for maximum MPG.

Honda CR-V Hybrid (Performance and Efficiency Balance): The Honda CR-V Hybrid demonstrates how advanced battery technology supports a balance between SUV practicality, performance, and fuel efficiency. Utilizing a compact Li-ion battery pack, the CR-V Hybrid’s system seamlessly integrates the electric motor with the Atkinson-cycle engine. The battery primarily supports the electric motor in urban driving, where it can frequently operate in EV mode, and provides robust power assist during acceleration. This setup allows a relatively large SUV to achieve impressive combined MPG figures, often in the high 30s. The efficient power delivery and rapid charge acceptance of the Li-ion battery are critical for both the immediate torque needed in an SUV and the constant energy recovery through regenerative braking, making it a highly efficient family vehicle.

Ford F-150 PowerBoost (Heavy-Duty Hybridization): Perhaps one of the most compelling examples of battery innovation pushing the boundaries of hybrid efficiency is the Ford F-150 PowerBoost. This full-size pickup truck integrates a powerful 3.5-liter EcoBoost engine with an electric motor and a 1.5 kWh Li-ion battery pack. The challenge here is not just fuel economy but also maintaining robust towing and hauling capabilities. The battery-electric system allows the F-150 PowerBoost to deliver immediate torque, improving acceleration and providing significant power for tasks without solely relying on the gasoline engine. The hybrid system enables the truck to operate in electric-only mode at lower speeds and offers substantial regenerative braking, significantly improving city MPG for a vehicle of its size and capability. This showcases how battery technology isn’t just for small, economy-focused cars but can deliver dramatic efficiency gains even in heavy-duty applications, providing better MPG while maintaining utility.

These examples illustrate that battery innovations are not just theoretical concepts but are actively integrated into a diverse range of hybrid vehicles, each leveraging the unique benefits of modern battery technology to deliver superior fuel economy and an enhanced driving experience. From compact sedans to full-size trucks, the battery remains the crucial enabler of their impressive MPG ratings.

Frequently Asked Questions

Q: What is the main difference between NiMH and Li-ion batteries in hybrids?

A: The main difference lies in their energy density and weight. Lithium-ion (Li-ion) batteries offer significantly higher energy density, meaning they can store more energy in a smaller and lighter package compared to Nickel-Metal Hydride (NiMH) batteries. This translates to better fuel efficiency due to reduced vehicle weight, longer electric-only driving ranges (especially in plug-in hybrids), and often better power delivery. Li-ion batteries also generally have a lower self-discharge rate, but some chemistries can be more sensitive to temperature extremes and require more sophisticated thermal management than NiMH.

Q: How does a hybrid battery improve fuel efficiency (MPG)?

A: A hybrid battery improves MPG in several key ways. Firstly, it enables electric-only driving at low speeds, eliminating fuel consumption during those periods. Secondly, it provides power assist to the gasoline engine during acceleration, reducing the engine’s workload and allowing it to operate in its most efficient range. Thirdly, and perhaps most crucially, it captures kinetic energy normally lost as heat during braking through a process called regenerative braking, converting it back into electricity to recharge the battery. This recovered energy can then be reused, significantly boosting efficiency, especially in city driving.

Q: How long do hybrid batteries typically last?

A: Modern hybrid batteries are designed to last for the lifetime of the vehicle, often exceeding 10-15 years or 150,000-200,000 miles. Most manufacturers offer extensive warranties on their hybrid batteries, typically 8 years/100,000 miles, with some states offering 10 years/150,000 miles due to specific emissions regulations. While batteries do degrade over time, meaning their capacity might slightly diminish, they rarely fail completely and typically continue to function adequately for the vehicle’s operational life. Factors like extreme temperatures, aggressive driving, and improper charging habits (for PHEVs) can influence degradation rates.

Q: Is replacing a hybrid battery expensive?

A: The cost of replacing a hybrid battery has significantly decreased over the years. While it can still be a substantial expense, typically ranging from $2,000 to $6,000 for a new pack (depending on the vehicle model and battery type), aftermarket options and reconditioned batteries can be less expensive. Many original batteries are also covered under a long warranty, so replacement is often not a concern for the original owner. Furthermore, declining battery costs due to technological advancements and increased production volumes suggest that future replacements will continue to become more affordable.

Q: What is regenerative braking and how does it relate to the battery?

A: Regenerative braking is a system in hybrid and electric vehicles that converts kinetic energy (motion) into electrical energy during deceleration or braking, instead of wasting it as heat through friction brakes. When the driver lifts off the accelerator or presses the brake, the electric motor reverses its function, acting as a generator to slow the car and simultaneously recharge the high-voltage battery. The battery is crucial here because it must be able to efficiently and quickly accept this recaptured electrical energy for storage and later redeployment, directly contributing to higher MPG.

Q: Do hybrid batteries need to be charged externally?

A: Most conventional (full) hybrid vehicles do not require external charging. Their batteries are automatically recharged by the gasoline engine and through regenerative braking. However, Plug-in Hybrid Electric Vehicles (PHEVs) do need to be charged externally, typically by plugging into a standard wall outlet or a dedicated charging station. This allows PHEVs to operate for a significant electric-only range before the gasoline engine activates, maximizing fuel efficiency and reducing emissions.

Q: What role does thermal management play in battery life and efficiency?

A: Thermal management is vital for maintaining the battery’s performance, lifespan, and safety. Batteries operate most efficiently within a specific temperature range; too hot or too cold, and their capacity, power output, and longevity are negatively affected. A sophisticated thermal management system (either air or liquid-cooled) ensures the battery stays at its optimal temperature, preventing premature degradation, maximizing its ability to accept charge from regenerative braking, and delivering consistent power to the electric motor, all of which are crucial for maintaining high MPG over time.

Q: Are solid-state batteries the future for hybrids?

A: Solid-state batteries hold immense promise for the future of hybrid (and electric) vehicles. They are expected to offer significantly higher energy density, faster charging capabilities, enhanced safety (due to a non-flammable solid electrolyte), and a longer lifespan compared to current Li-ion batteries. If successfully commercialized at scale, solid-state batteries could enable even smaller and lighter battery packs for hybrids, leading to greater electric range, even better fuel economy, and potentially faster charging for PHEVs. While still in development, they represent a significant step forward in battery technology.

Q: How do battery innovations affect a hybrid’s resale value?

A: Battery innovations positively impact a hybrid’s resale value by contributing to its long-term reliability and efficiency. As battery technology improves, batteries last longer and perform better, reducing concerns about costly replacements for future owners. Hybrids with more advanced, durable, and efficient battery systems will likely retain their value better, as they continue to deliver superior fuel economy and performance throughout their lifespan, making them more attractive in the used car market.

Q: What are the environmental benefits of advanced hybrid batteries?

A: Advanced hybrid batteries contribute significantly to environmental benefits. By enabling higher MPG, they reduce overall gasoline consumption, leading to lower greenhouse gas emissions and a smaller carbon footprint per mile driven. The improved efficiency means fewer fossil fuels are burned. Furthermore, advancements like the move towards LFP batteries and future chemistries are exploring more sustainable and ethically sourced materials, reducing reliance on rare or conflict minerals. The longer lifespan of modern batteries also means less waste and a more sustainable product lifecycle.

Key Takeaways

- Battery is Core to MPG: The battery is not just an accessory but the central component enabling electric-only driving, power assist, and regenerative braking, all critical for hybrid fuel efficiency.

- Li-ion Revolution: The shift from NiMH to Lithium-ion batteries brought significant gains in energy density, power density, and weight reduction, directly enhancing hybrid MPG.

- Chemistry Matters: Different Li-ion chemistries (NMC, LFP, NCA) offer varied balances of energy density, power, safety, and lifespan, allowing manufacturers to optimize for specific hybrid needs.

- Thermal Management is Crucial: Sophisticated thermal systems (especially liquid cooling) ensure batteries operate at optimal temperatures, preserving efficiency, power, and lifespan, thus sustaining high MPG.

- BMS as the Brain: Battery Management Systems (BMS) and smart software optimizations meticulously monitor and control battery operations, maximizing energy capture and delivery for superior fuel economy.

- Weight and Size Impact: Smaller, lighter battery packs, enabled by higher energy density, reduce overall vehicle weight, directly contributing to better MPG and improved vehicle dynamics.

- Regenerative Braking Power: Efficient batteries are key to maximizing energy recovery through regenerative braking, which is a major driver of hybrid efficiency, particularly in urban settings.

- Future is Bright: Next-generation battery technologies like solid-state batteries promise even higher energy density, faster charging, and enhanced safety, poised to further revolutionize hybrid MPG.

- Real-World Impact: These innovations are evident in various hybrid models, from the pioneering Toyota Prius to the robust Ford F-150 PowerBoost, delivering tangible MPG benefits to consumers.

Conclusion

The journey of hybrid electric vehicles, from their conceptualization to their widespread adoption, is inextricably linked to the remarkable advancements in battery technology. What began with the reliable, albeit limited, Nickel-Metal Hydride battery has evolved into a dynamic landscape dominated by increasingly sophisticated Lithium-ion chemistries, each pushing the boundaries of what is possible in terms of energy storage, power delivery, and longevity. These innovations are not mere technical curiosities; they are the fundamental enablers of the impressive MPG figures that make hybrid vehicles an attractive and sustainable choice for millions of drivers globally.

From the precise thermal management systems that cradle batteries in their optimal operating window to the intelligent Battery Management Systems that orchestrate their every charge and discharge cycle, every component plays a critical role in maximizing efficiency. Regenerative braking, a hallmark of hybrid technology, owes its effectiveness to batteries capable of rapidly absorbing and redeploying captured kinetic energy. Moreover, the relentless pursuit of lighter, more compact, and more energy-dense battery packs directly translates into lighter vehicles that require less fuel to move, a virtuous cycle of efficiency.

As we look to the horizon, the promise of next-generation technologies like solid-state batteries suggests an even more exciting future. These potential breakthroughs hold the key to unlocking unprecedented levels of electric range, charging speed, and safety, which will further blur the lines between hybrids and pure electric vehicles, driving MPG figures to new heights. The evolution of battery technology is not just about extending range or reducing emissions; it is about fundamentally redefining our relationship with transportation, making it cleaner, more efficient, and more sustainable. The continuous innovation in hybrid batteries stands as a testament to human ingenuity in the pursuit of a greener, more fuel-efficient tomorrow.