The automotive industry is undergoing an unprecedented transformation, with hybrid electric vehicles (HEVs) playing a pivotal role in bridging the gap between traditional internal combustion engines and fully electric vehicles. Hybrids offer a compelling blend of fuel efficiency, reduced emissions, and the convenience of traditional refueling. At the heart of every hybrid lies its battery system, a complex power source that dictates everything from range and acceleration to overall vehicle lifespan and cost. While current lithium-ion battery technology has served hybrids well, the pursuit of greater efficiency, enhanced performance, and increased sustainability is driving an intense focus on what we call Next-Gen Chemistries.

This deep dive will explore the revolutionary advancements in battery materials and architectures that are poised to redefine the capabilities of hybrid powertrains. We will journey beyond the familiar boundaries of conventional lithium-ion, delving into the exciting potentials of solid-state, lithium-sulfur, sodium-ion, and other innovative chemistries. Our exploration will cover their fundamental principles, the immense advantages they offer, the significant challenges they face, and their practical implications for the future of hybrid mobility. Prepare to unlock a new understanding of how these cutting-edge chemistries are set to unlock unprecedented efficiencies, safety, and performance in the next generation of hybrid electric vehicles, fundamentally reshaping our sustainable transportation landscape.

The Foundational Role of Batteries in Hybrid Powertrains

In a hybrid electric vehicle, the battery system is far more than just a power reservoir; it is a dynamic component that enables the very essence of hybrid functionality. Unlike pure electric vehicles that rely solely on battery power for propulsion, hybrids use their batteries in concert with a gasoline engine. This synergistic relationship allows for numerous benefits, such as capturing kinetic energy through regenerative braking, providing supplemental power for acceleration, and enabling all-electric driving at lower speeds or for short distances, particularly in Plug-in Hybrid Electric Vehicles (PHEVs).

The demands placed on hybrid batteries are unique. They require high power density for rapid energy discharge and recharge during acceleration and regenerative braking, often within very short bursts. Simultaneously, they need a reasonable energy density to provide an adequate all-electric range in PHEVs or to sustain engine-off operation in full hybrids. Furthermore, these batteries must endure tens of thousands, if not hundreds of thousands, of charge and discharge cycles over the vehicle’s lifetime, often under varying environmental conditions. Thermal management is critical to maintaining optimal performance and extending battery life, as is the need for inherent safety to prevent thermal runaway events. The continuous innovation in battery chemistry and design is directly aimed at optimizing these critical parameters, pushing the boundaries of what hybrid vehicles can achieve in terms of efficiency, performance, and long-term reliability.

Limitations of Current Lithium-Ion Technology in Hybrid Applications

Lithium-ion batteries have been the undisputed champions of portable electronics and electric vehicles for decades, and they have performed admirably in hybrid applications. Their relatively high energy density and good power characteristics made them a significant improvement over older nickel-metal hydride (NiMH) batteries. However, as hybrid technology evolves and demands for greater efficiency, longer electric ranges, and faster charging times intensify, the inherent limitations of traditional lithium-ion chemistries become more apparent.

One primary concern revolves around energy density. While sufficient for many hybrids, pushing for larger all-electric ranges in PHEVs using conventional Li-ion often means larger, heavier, and more expensive battery packs. This adds weight to the vehicle, counteracting some of the efficiency gains. Another challenge is thermal management. Liquid electrolytes, a core component of traditional Li-ion cells, are flammable and require sophisticated cooling systems to prevent overheating and potential thermal runaway, which is a significant safety consideration. These cooling systems add complexity, weight, and cost. Furthermore, the reliance on certain critical materials like cobalt, found in many high-performance lithium-ion cathodes, raises concerns about supply chain stability, ethical sourcing, and environmental impact. The drive for faster charging, especially in PHEVs, also pushes the limits of current Li-ion technology, as rapid charging can accelerate degradation and generate significant heat. These factors collectively highlight the need for revolutionary advancements, not just incremental improvements, in battery chemistry to meet the ambitious goals of next-generation hybrid powertrains.

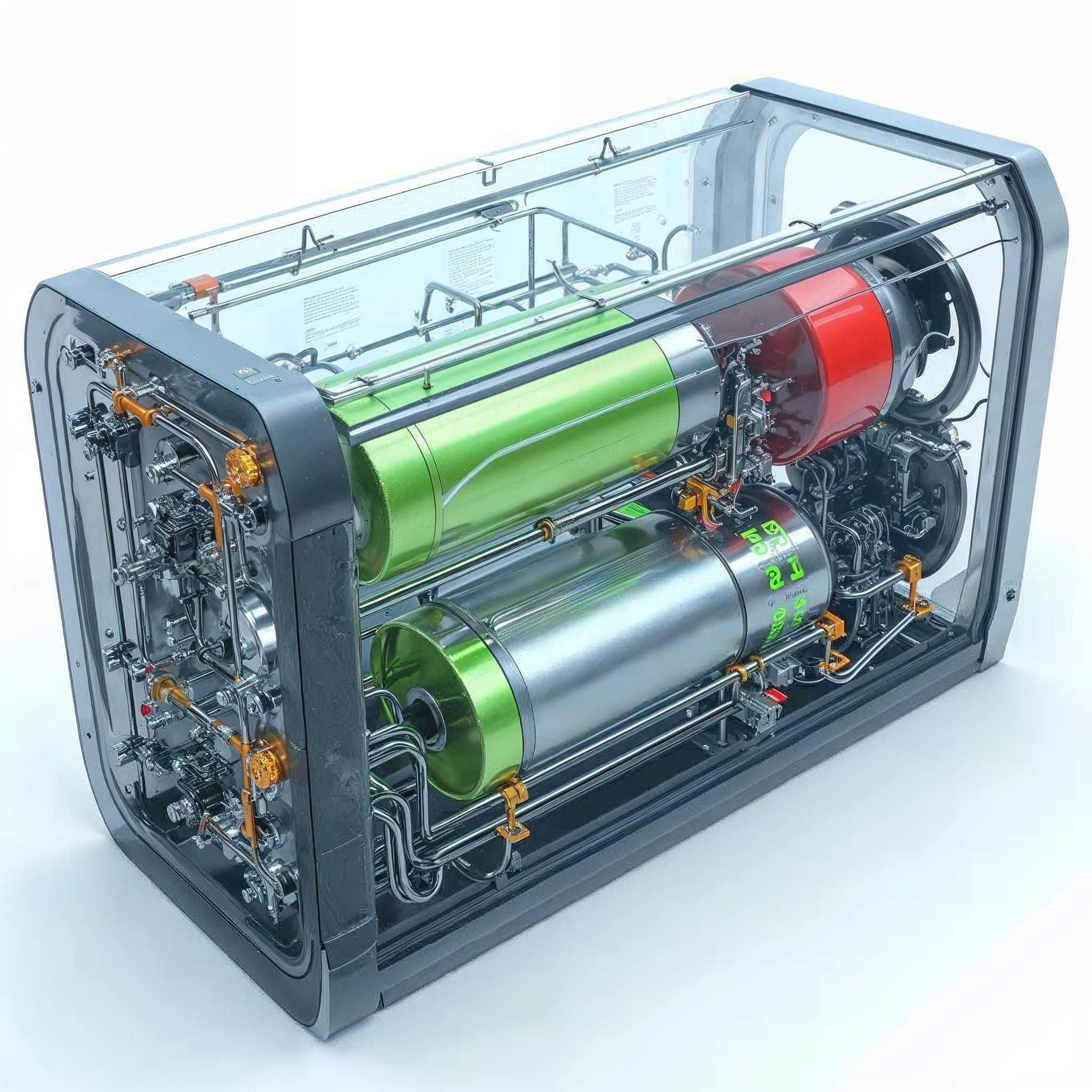

Solid-State Batteries: The Promise of Enhanced Safety and Performance

Among the most anticipated next-gen chemistries, Solid-State Batteries (SSBs) stand out as a potential game-changer for hybrid and electric vehicles alike. The fundamental difference lies in replacing the flammable liquid electrolyte found in conventional lithium-ion batteries with a solid material. This seemingly simple change unlocks a cascade of significant advantages that directly address many of the limitations of current battery technology.

The primary appeal of SSBs is their dramatically improved safety profile. By eliminating the volatile liquid electrolyte, the risk of thermal runaway, fire, and explosion is substantially reduced, making SSBs inherently safer. This safety dividend allows for more compact packaging and potentially simpler, lighter cooling systems. Beyond safety, SSBs promise a significant leap in energy density. The solid electrolyte can enable the use of lithium metal anodes, which boast a theoretical energy capacity ten times higher than traditional graphite anodes. This could translate into smaller, lighter battery packs that deliver much longer all-electric ranges for PHEVs or allow for more flexible vehicle designs. Furthermore, some solid-state designs show promise for extremely fast charging rates and an extended cycle life due to the stable nature of the solid electrolyte in preventing dendrite formation, a common issue in liquid electrolyte systems with lithium metal. Companies like Toyota, QuantumScape, and Solid Power are heavily investing in SSBs, demonstrating the industry’s confidence in their potential. While challenges remain, particularly in achieving high ion conductivity at room temperature, ensuring robust interfaces between solid components, and scaling manufacturing economically, the vision of safer, higher-performance, and longer-lasting batteries for hybrid powertrains makes solid-state technology a cornerstone of future battery innovation.

Lithium-Sulfur (Li-S) Batteries: High Energy Density and Material Abundance

Lithium-Sulfur (Li-S) batteries represent another compelling next-gen chemistry, offering a different pathway to high energy density and potentially lower costs. The allure of Li-S technology stems from sulfur’s abundance, low cost, and remarkably high theoretical specific energy (around 2500 Wh/kg at the cell level, significantly higher than current Li-ion’s 200-300 Wh/kg). This promises much lighter battery packs for a given energy capacity, a critical factor for improving vehicle efficiency and performance, especially in larger PHEVs or even light-duty commercial hybrid applications.

The operational principle of Li-S batteries involves a lithium metal anode and a sulfur cathode. During discharge, lithium ions migrate to the sulfur cathode, reacting to form various lithium sulfides. The abundance of sulfur, a byproduct of the petroleum industry, eliminates concerns about rare or ethically challenging materials like cobalt, contributing to a more sustainable supply chain. Despite these attractive features, Li-S batteries face significant hurdles. The most prominent is the “polysulfide shuttle” effect, where intermediate lithium polysulfide species dissolve into the electrolyte and migrate to the anode, reacting with lithium metal. This leads to irreversible capacity loss, poor Coulombic efficiency, and rapid degradation of cycle life. The volumetric energy density also tends to be lower than Li-ion due to the low density of sulfur and the need for large electrolyte volumes. Additionally, the lithium metal anode, while offering high capacity, is prone to dendrite formation, posing safety risks. Extensive research is focused on developing novel cathode architectures, protective interlayers for lithium metal, and advanced electrolytes to mitigate these issues. Companies like OXIS Energy (though recently ceased operations, the research continues broadly) and Sion Power have been at the forefront of Li-S development, aiming to overcome these challenges and bring this high-potential chemistry to market for applications requiring superior energy density, such as extended-range PHEVs.

Sodium-Ion (Na-Ion) Batteries: The Abundant, Cost-Effective Alternative

While lithium has dominated the rechargeable battery landscape, Sodium-Ion (Na-Ion) batteries are emerging as a powerful and highly sustainable alternative, particularly for applications where cost-effectiveness, abundant materials, and enhanced safety are paramount. The fundamental chemistry of Na-ion batteries mirrors that of Li-ion, but crucially, it replaces lithium with sodium. Sodium is one of the most abundant elements on Earth, readily available from sources like seawater and rock salt, making it significantly cheaper and free from geopolitical supply chain constraints associated with lithium and cobalt.

The advantages of Na-ion batteries for hybrid powertrains are compelling. Firstly, their cost-effectiveness makes them ideal for mass-market mild hybrids or even full hybrids where the battery pack size can be optimized for power rather than absolute range. Secondly, Na-ion batteries inherently possess a higher thermal stability compared to many Li-ion chemistries, translating to improved safety and potentially simpler, less expensive thermal management systems. This reduced safety risk is a significant benefit for automotive integration. Furthermore, Na-ion batteries perform exceptionally well in extremely cold temperatures, which is an advantage for vehicles operating in diverse climates. However, Na-ion technology currently lags behind Li-ion in terms of energy density and cycle life. Sodium ions are larger and heavier than lithium ions, leading to slower diffusion kinetics and lower specific energy for comparable cell designs. Research is actively focused on developing high-performance electrode materials (such as Prussian blue analogues, layered oxides, and hard carbon for anodes) and optimized electrolytes to enhance energy density, power capability, and cycle stability. Companies like CATL in China are heavily investing in Na-ion technology, with plans for mass production and integration into various applications, including potentially the entry-level hybrid vehicle market, demonstrating a clear path forward for this environmentally conscious and economically viable battery solution.

Advanced Cathode and Anode Materials: Boosting Performance in Hybrid Cells

Beyond entirely new chemistries, significant advancements are also being made in refining the components of existing and next-gen lithium-ion derivatives, particularly in the cathode and anode materials. These innovations are crucial for pushing the boundaries of energy density, power output, cycle life, and safety in hybrid battery cells.

On the cathode side, the trend is towards high-nickel materials such as Nickel-Manganese-Cobalt (NMC) and Nickel-Cobalt-Aluminum (NCA) oxides with increasingly higher nickel content (e.g., NMC 811, NMC 9.5.5, NCA with very high nickel). Increasing nickel content boosts energy density, allowing for more compact and lighter battery packs for a given capacity. However, higher nickel content often comes with trade-offs in thermal stability and cycle life, requiring careful material engineering and advanced electrolyte formulations. Companies like LG Energy Solution and Panasonic are continuously refining these materials.

For anode materials, silicon-based anodes are a primary focus. Silicon has a theoretical specific capacity ten times higher than graphite, meaning it can store significantly more lithium ions per unit mass. Integrating even a small percentage of silicon into graphite anodes can dramatically increase the overall energy density of a cell. The main challenge with silicon is its massive volume expansion (up to 400%) during lithiation, which can cause electrode pulverization and rapid capacity fade. Nanostructured silicon (nanowires, nanoparticles) and silicon-carbon composites are being developed to mitigate this expansion and maintain electrode integrity. Tesla, for instance, has been working on silicon-containing anodes for years.

Another frontier is lithium metal anodes. While facing severe dendrite formation issues, a stable lithium metal anode coupled with a high-capacity cathode could offer the ultimate energy density (the basis for many solid-state and Li-S concepts). Research involves solid-state electrolytes, protective coatings, and advanced binders to stabilize the lithium metal interface. Furthermore, the incorporation of graphene and carbon nanotubes as conductive additives or structural frameworks in both cathodes and anodes can significantly improve electrical conductivity, mechanical stability, and rates of ion diffusion, leading to better power performance and faster charging capabilities. These material science breakthroughs are continuously optimizing existing battery paradigms while paving the way for the successful integration of entirely new chemistries.

Intelligent Battery Management Systems and Thermal Control for Next-Gen Chemistries

The advent of next-gen battery chemistries, with their unique operating characteristics and sensitivities, necessitates equally advanced Battery Management Systems (BMS) and sophisticated thermal control strategies. A BMS is the brain of the battery pack, overseeing every aspect of its operation to ensure safety, optimize performance, and extend lifespan. For next-gen chemistries, the role of the BMS becomes even more critical due to the sometimes novel degradation mechanisms and thermal sensitivities.

An intelligent BMS for next-gen hybrid batteries must perform several key functions with enhanced precision. It monitors individual cell voltages, temperatures, and currents with extreme accuracy, detecting even minute deviations that could indicate a problem. For chemistries like Li-S or Na-ion, which may have different charge/discharge profiles and voltage plateaus compared to Li-ion, the BMS needs to adapt its state-of-charge (SoC) and state-of-health (SoH) estimations accordingly. Predictive algorithms, often employing artificial intelligence and machine learning, are becoming standard to anticipate potential issues, optimize charging and discharging cycles to minimize degradation, and balance cells more effectively, especially over a very long operational life.

Thermal management is intertwined with the BMS and is paramount for hybrid vehicles, where batteries often experience rapid, fluctuating loads and ambient temperatures. Next-gen chemistries, particularly solid-state batteries, may have specific optimal temperature ranges for ionic conductivity, or may be more sensitive to temperature extremes. Advanced thermal control systems move beyond simple air or liquid cooling. They might include direct immersion cooling, phase-change materials, or even microfluidic cooling channels embedded within the battery pack, allowing for precise temperature regulation at the cell level. This precision helps to prevent localized hot spots, maintain uniform cell temperatures, and protect the delicate chemistry from degradation due to overheating or excessive cooling. By intelligently managing both the electrical and thermal aspects, a sophisticated BMS ensures that next-gen hybrid batteries can operate at their peak efficiency, safely, and for the entire intended lifespan of the vehicle, truly unlocking their full potential.

Comparison Tables

Table 1: Comparison of Key Battery Chemistries for Hybrid Powertrains

| Feature / Chemistry | Current Li-ion (NMC/NCA) | Solid-State Battery | Lithium-Sulfur (Li-S) | Sodium-Ion (Na-Ion) |

|---|---|---|---|---|

| Theoretical Energy Density (Wh/kg) | 200-300 | 400-500+ (potential) | 500-600+ (potential) | 120-160 (current) |

| Safety Profile | Good (liquid electrolyte is flammable) | Excellent (non-flammable solid electrolyte) | Good (lithium metal anode a concern) | Excellent (thermally stable, abundant) |

| Power Density | Very Good | Potentially Excellent | Good (requires advanced design) | Good (can be optimized for power) |

| Cycle Life | 800-2000+ cycles | Potentially 2000-5000+ cycles | 100-300 cycles (currently limited) | 500-2000+ cycles (improving) |

| Cost per kWh | Moderate (decreasing) | High (currently, R&D phase) | Potentially Low (abundant S) | Low (abundant Na, no Co) |

| Key Challenges | Thermal management, material sourcing | Scaling manufacturing, interface issues, cost | Polysulfide shuttle, volumetric energy density, dendrites | Lower energy density, cycle life improvement |

| Readiness Level | Mature, commercialized | Early to Mid-stage R&D | Early-stage R&D | Mid-stage R&D / Niche commercialization |

Table 2: Evolution of Hybrid Powertrain Battery Performance Parameters

| Parameter | Early Hybrid Batteries (e.g., NiMH, early Li-ion) | Current Hybrid Batteries (Advanced Li-ion) | Next-Gen Hybrid Batteries (Solid-State, Li-S, Na-ion) |

|---|---|---|---|

| Specific Energy (Wh/kg) | 50-100 | 150-250 | 300-600+ (estimated) |

| Specific Power (W/kg) | 500-1000 | 1000-2000+ | 2000-4000+ (estimated) |

| Charge Time (for 80% SoC) | Hours (PHEV), minutes (regenerative) | 30-60 minutes (PHEV), seconds (regenerative) | 5-15 minutes (PHEV fast-charge potential) |

| Battery Lifespan (cycles) | 1000-2000 | 2000-4000 | 3000-10000+ (estimated) |

| Operating Temperature Range (°C) | -20 to 45 | -30 to 50 | -40 to 60+ (potential with advanced materials) |

| Cobalt Content | Varies, some with none (NiMH) | Moderate to High (NMC/NCA) | Potentially Low or None (Solid-State, Li-S, Na-ion) |

Practical Examples and Real-World Scenarios

The theoretical advancements in next-gen chemistries find their true value when translated into tangible improvements for hybrid vehicles and their drivers. Let’s explore some practical examples and real-world scenarios where these new technologies are making a difference or are poised to in the near future:

- Extended All-Electric Range for Plug-in Hybrid Electric Vehicles (PHEVs): Imagine a PHEV equipped with a solid-state battery. Today, a typical PHEV might offer 30-50 miles of electric range. With the higher energy density of SSBs, that range could double or even triple, allowing many commuters to complete their daily drives entirely on electric power without needing to tap into the gasoline engine. This would dramatically reduce fuel consumption and local emissions, making PHEVs even more compelling for urban environments. For instance, Toyota has been a major proponent and investor in solid-state battery technology, aiming to integrate it into its future electrified lineup, potentially starting with hybrids.

- Lighter and More Efficient Hybrid Architectures: If lithium-sulfur batteries can overcome their cycle life challenges, their exceptional gravimetric energy density (energy per unit of weight) could lead to significantly lighter battery packs. For a full hybrid, a lighter battery means the vehicle carries less inert weight, improving overall fuel efficiency. For high-performance hybrid sports cars or commercial hybrids, this weight reduction could translate into better acceleration, handling, and payload capacity. The focus on reducing vehicle weight is a constant in automotive engineering, and Li-S offers a promising path.

- Cost-Effective Mild Hybrids and Entry-Level PHEVs: Sodium-ion batteries, with their abundance of materials and lower manufacturing costs, could democratize hybrid technology. Currently, the battery pack is one of the most expensive components in a hybrid. Na-ion could enable more affordable mild hybrids (like 48V systems) that offer basic electric assist, stop-start functionality, and regenerative braking benefits at a lower price point, making hybrids accessible to a broader market segment. Chinese battery giant CATL, for example, has announced plans for Na-ion battery production for various applications, including potentially lower-cost EVs and hybrids, aiming for widespread adoption.

- Enhanced Safety for Urban Fleets: The inherent thermal stability and non-flammable nature of solid-state and advanced Na-ion chemistries would be a significant boon for urban taxi fleets or ride-sharing services that operate hybrids. These vehicles experience frequent stop-and-go driving and constant charging/discharging cycles, which can stress conventional batteries. Improved safety characteristics mean less risk of thermal events, enhancing passenger and driver confidence, and potentially reducing insurance premiums for fleet operators.

- Faster Charging for On-the-Go Lifestyles: While full EVs benefit most from ultra-fast charging, PHEVs can also gain significantly. A solid-state battery capable of accepting a rapid charge could allow a PHEV driver to top up their electric range during a quick coffee break or while grocery shopping, essentially extending their all-electric capabilities throughout the day without range anxiety. This convenience factor is a key driver for consumer adoption.

- Sustainability and Reduced Environmental Impact: The shift towards chemistries like Li-S (using abundant sulfur) and Na-ion (using abundant sodium) drastically reduces reliance on scarce and often controversially sourced materials like cobalt. This provides car manufacturers with more robust and ethical supply chains, aligns with global sustainability goals, and contributes to a greener automotive ecosystem from material extraction to end-of-life recycling. The ability to use more common and less toxic materials contributes to a better overall environmental footprint for hybrid vehicles.

Frequently Asked Questions About Next-Gen Hybrid Battery Chemistries

Q: What exactly are “Next-Gen Chemistries” in the context of hybrid batteries?

A: “Next-Gen Chemistries” refer to advanced battery technologies that go beyond the capabilities of current conventional lithium-ion batteries. These include chemistries like solid-state, lithium-sulfur, and sodium-ion batteries, as well as significant advancements in existing lithium-ion components like silicon anodes or high-nickel cathodes. Their goal is to offer substantial improvements in energy density, power output, safety, cycle life, and sustainability for hybrid electric vehicles.

Q: Why are new battery chemistries needed for hybrid electric vehicles if current lithium-ion works?

A: While current lithium-ion batteries perform well, they have limitations that new chemistries aim to overcome. These include challenges with energy density (for longer EV range in PHEVs without adding excessive weight), thermal management (due to flammable liquid electrolytes), reliance on critical materials (like cobalt), and the desire for even faster charging and longer lifespan. Next-gen chemistries promise to deliver higher efficiency, better performance, enhanced safety, and greater sustainability.

Q: What is a solid-state battery, and why is it considered a holy grail for hybrids?

A: A solid-state battery replaces the liquid electrolyte in traditional lithium-ion batteries with a solid material. It is considered a “holy grail” because this change offers several profound benefits: significantly improved safety (no flammable liquid), much higher energy density (potentially allowing for lithium metal anodes), faster charging capabilities, and a longer cycle life. For hybrids, this means smaller, lighter, safer battery packs with extended all-electric ranges for PHEVs and enhanced performance.

Q: What are the main challenges preventing widespread adoption of solid-state batteries today?

A: Despite their promise, solid-state batteries face several significant hurdles. These include achieving high ion conductivity in the solid electrolyte at room temperature, ensuring stable and low-resistance interfaces between the solid electrolyte and electrode materials, scaling up complex manufacturing processes for mass production, and ultimately, reducing their current high cost to be competitive with conventional Li-ion batteries. Intense research and development are ongoing to address these issues.

Q: How do Lithium-Sulfur (Li-S) batteries differ from traditional Li-ion, and what are their benefits for hybrids?

A: Lithium-Sulfur batteries use a lithium metal anode and a sulfur cathode, in contrast to Li-ion’s graphite anode and metal oxide cathode. The primary benefit of Li-S is its exceptionally high theoretical energy density, which is several times greater than Li-ion. This could lead to much lighter battery packs for a given energy capacity, improving vehicle efficiency. Additionally, sulfur is abundant and low-cost, offering a more sustainable alternative to cobalt-rich Li-ion cathodes.

Q: What are the primary advantages of Sodium-Ion (Na-Ion) batteries for hybrid applications?

A: Sodium-Ion batteries replace lithium with sodium, an incredibly abundant and inexpensive element. Their main advantages for hybrids include significantly lower cost due to material abundance (no lithium, cobalt, or nickel), excellent thermal stability leading to enhanced safety, and good performance in cold temperatures. While currently having a lower energy density than Li-ion, Na-ion is ideal for cost-sensitive applications like mild hybrids or as a sustainable alternative in full hybrids.

Q: Will these new next-gen batteries be affordable for the average consumer?

A: The affordability of next-gen batteries varies by chemistry. Sodium-ion batteries are expected to be highly cost-effective due to the abundance of sodium. Lithium-sulfur also has the potential for lower costs due to cheaper sulfur. Solid-state batteries, initially, will likely be more expensive due to complex manufacturing and early-stage development, but costs are expected to decrease with scale. The ultimate goal for all these chemistries is to offer compelling performance benefits at a competitive price point, making hybrid vehicles more accessible and attractive.

Q: How do these next-gen technologies contribute to improved safety in hybrid vehicles?

A: Many next-gen chemistries inherently offer improved safety. Solid-state batteries, by replacing flammable liquid electrolytes with solid ones, virtually eliminate the risk of thermal runaway and fire. Sodium-ion batteries generally exhibit higher thermal stability than many Li-ion chemistries, reducing the likelihood of overheating. While lithium-sulfur batteries still use a lithium metal anode (a safety concern), research is focused on protective layers to mitigate dendrite formation and enhance overall safety. The aim is to create battery systems that are fundamentally safer in operation.

Q: What role does an advanced Battery Management System (BMS) play with these new chemistries?

A: An advanced BMS is absolutely crucial for next-gen chemistries. It acts as the brain of the battery, monitoring and managing cell voltages, temperatures, and currents with extreme precision. For new chemistries, the BMS must adapt to unique charge/discharge characteristics, optimize thermal control (which might be more complex or precise for specific chemistries), and employ sophisticated algorithms to predict and prevent degradation, ensuring the battery operates safely, efficiently, and with maximum lifespan, even with novel materials and behaviors.

Q: When can we expect these next-gen battery technologies to be widely available in hybrid cars?

A: The timeline varies for each chemistry. Sodium-ion batteries are already seeing limited commercial deployment in some niche applications and could appear in entry-level hybrids within the next 3-5 years. Solid-state batteries are projected to be in commercial vehicles, potentially starting with high-end models or specialized hybrids, by the late 2020s or early 2030s, with Toyota being a key player. Lithium-sulfur batteries are likely further out, perhaps in the 2030s, as they still face significant challenges with cycle life and degradation that require more fundamental breakthroughs before widespread automotive adoption.

Key Takeaways: The Future of Hybrid Battery Technology

- Next-gen chemistries are essential for pushing the boundaries of efficiency, performance, and sustainability in hybrid electric vehicles beyond current lithium-ion capabilities.

- Solid-state batteries promise unparalleled safety, higher energy density, and faster charging by replacing liquid electrolytes with solid materials, though manufacturing and cost remain challenges.

- Lithium-sulfur batteries offer exceptionally high theoretical energy density and rely on abundant sulfur, making them lighter and potentially more sustainable, but struggle with cycle life and polysulfide shuttle effects.

- Sodium-ion batteries provide a cost-effective and highly sustainable alternative, leveraging abundant sodium, offering excellent safety and cold-weather performance, though with currently lower energy density than Li-ion.

- Advanced materials like high-nickel cathodes and silicon anodes are boosting the performance of existing Li-ion derivatives, increasing energy density and capacity.

- Intelligent Battery Management Systems (BMS) and sophisticated thermal management are critical for optimizing the safety, performance, and longevity of these new, sensitive chemistries in hybrid applications.

- Real-world impacts include extended all-electric ranges for PHEVs, lighter vehicle architectures, more affordable hybrid options, enhanced safety for vehicle fleets, and significant steps toward more sustainable automotive manufacturing.

- While some chemistries are closer to commercialization than others, the collective effort in developing these next-gen batteries is rapidly accelerating the evolution of hybrid powertrains.

Conclusion: A Brighter, More Efficient Hybrid Future

The journey towards truly sustainable and efficient transportation is complex, and hybrid electric vehicles are a crucial stepping stone. As we look to the horizon, it is clear that the future of hybrid powertrains is intricately linked to the revolution unfolding in battery chemistry. The shift from incremental improvements in existing lithium-ion technology to the transformative potential of next-gen chemistries like solid-state, lithium-sulfur, and sodium-ion batteries is not merely an engineering feat; it represents a paradigm shift.

These cutting-edge advancements promise to unlock unprecedented efficiencies, extended electric ranges, enhanced safety, and significant reductions in reliance on scarce materials. From enabling daily commutes entirely on electric power in a PHEV, to making hybrid technology more affordable and accessible for a broader demographic, the impact of these chemistries will be profound. While challenges in manufacturing, cost-reduction, and long-term durability remain for many of these nascent technologies, the pace of innovation is relentless. The collaborative efforts of researchers, manufacturers, and governments worldwide are paving the way for a future where hybrid vehicles are not just an interim solution, but a highly optimized, environmentally conscious, and powerfully efficient mode of transportation, driving us towards a cleaner and greener tomorrow, one advanced battery cell at a time.