The Evolution of Battery Technology in Hybrid Electric Vehicles

In the dynamic world of hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs), the battery is truly the heart of the system. It dictates range, acceleration, efficiency, and ultimately, the vehicle’s overall lifespan. However, this sophisticated component is highly sensitive to one often-overlooked factor: temperature. The art and science of maintaining an optimal operating temperature for hybrid batteries, known as thermal management, is not merely a technical detail; it is a critical differentiator that profoundly impacts performance, durability, and safety. This comprehensive guide will delve deep into the ‘Thermal Management Secrets’ that engineers employ to push the boundaries of hybrid battery technology, ensuring your electrified ride remains efficient and reliable for years to come.

From the bustling city streets to the open highway, a hybrid battery experiences a constant dance of charging and discharging, generating heat as it works. Unchecked, this heat can be a battery’s worst enemy, leading to accelerated degradation, reduced power output, and in extreme cases, safety hazards. Conversely, overly cold temperatures can equally diminish performance and efficiency. Therefore, precise thermal control is paramount. We will explore the ingenious strategies, from passive cooling solutions to advanced active systems and future innovations, that allow hybrid batteries to thrive under diverse operating conditions, contributing significantly to the ongoing evolution of battery technology in hybrid electric vehicles.

1. The Critical Role of Temperature in Battery Health

Imagine a high-performance athlete trying to compete in extreme heat or bitter cold; their performance would undoubtedly suffer. The same principle applies to hybrid batteries. Lithium-ion batteries, the predominant technology in modern HEVs and PHEVs, are electrochemical marvels, but their internal chemical reactions are highly temperature-dependent. There exists a relatively narrow ‘sweet spot’ or optimal temperature window, typically between 20°C and 35°C (68°F and 95°F), where these batteries perform at their peak efficiency, power output, and maintain their longest lifespan.

1.1. The Perils of High Temperatures

Excessive heat is arguably the greatest adversary to battery longevity. When a battery operates above its optimal temperature range, several detrimental effects occur:

- Accelerated Capacity Fade: High temperatures significantly speed up parasitic side reactions within the battery cells. These reactions consume active lithium, leading to the formation of an unstable Solid Electrolyte Interphase (SEI) layer on the anode. This layer grows thicker and more resistive over time, reducing the battery’s ability to store and release energy, manifesting as a permanent loss of capacity.

- Increased Internal Resistance: Heat can cause the electrolyte to decompose and the electrodes to degrade, increasing the battery’s internal resistance. This means the battery has to work harder to deliver power, generating even more heat in a vicious cycle, and resulting in lower power output and efficiency.

- Structural Degradation: Prolonged exposure to high temperatures can cause mechanical stress within the battery cells, leading to cracking of electrode materials and separator damage. This physical degradation further compromises performance and safety.

- Risk of Thermal Runaway: In extreme cases, unchecked heat can lead to a phenomenon known as thermal runaway. This is a chain reaction where increasing temperature causes exothermic chemical reactions, which in turn generate more heat, leading to a rapid and uncontrollable rise in temperature that can result in fire or explosion. While highly rare in HEVs due to robust safety systems, the risk underscores the absolute necessity of effective thermal management.

1.2. The Challenges of Low Temperatures

While often less destructive than heat, cold temperatures also pose significant challenges for hybrid batteries:

- Reduced Power Output: At low temperatures, the electrolyte becomes more viscous, and the diffusion rate of lithium ions through the electrolyte and into the electrode materials slows down. This increased resistance to ion movement directly translates to a reduced ability to deliver peak power, leading to sluggish acceleration and diminished regenerative braking capabilities.

- Decreased Usable Capacity: Although the total stored energy might not be lost, the battery’s ability to discharge a significant portion of its capacity at high currents is hampered in cold weather. This effectively reduces the ‘usable’ capacity, potentially impacting electric-only range in PHEVs or overall hybrid efficiency.

- Slower Charging Rates: Charging a cold battery is problematic. The slower lithium-ion kinetics can lead to lithium plating on the anode, a damaging process where metallic lithium deposits on the electrode surface. This is irreversible, degrades the battery, and can significantly reduce its lifespan and safety. Consequently, battery management systems often restrict charging power in cold conditions, leading to longer charging times.

Understanding these temperature sensitivities is the first step in appreciating the sophisticated engineering behind hybrid vehicle battery thermal management systems (TMS).

2. Understanding Heat Generation in Hybrid Batteries

To effectively manage heat, one must first understand its origins. Hybrid batteries, despite their efficiency, are not 100% perfect energy converters, and thus, generate heat during operation. This heat is a byproduct of several electrochemical and electrical processes:

2.1. Ohmic Heating (Joule Heating)

This is arguably the most significant source of heat generation, often referred to as I2R losses. As current flows through any resistive component, electrical energy is converted into heat. In a battery, this resistance comes from:

- Internal Resistance of Cells: Each individual battery cell has a certain internal resistance (sum of ohmic, charge transfer, and mass transport resistances). During charging and discharging, current flowing through this resistance generates heat. High currents, common during rapid acceleration or strong regenerative braking, amplify this effect dramatically.

- Interconnects and Busbars: The electrical pathways connecting individual cells into modules and modules into a battery pack also possess resistance, albeit small. High currents flowing through these connections contribute to overall heat generation within the pack.

2.2. Electrochemical Heat (Entropy Change)

Beyond simple electrical resistance, the chemical reactions themselves within the battery cells can either absorb or release heat. This is governed by the entropy change of the reaction:

- Exothermic Reactions: During certain phases of charge and discharge, the electrochemical reactions release heat. This is typically more pronounced during discharge (power delivery) and especially under high C-rates (high current relative to capacity).

- Endothermic Reactions: Conversely, some reactions can absorb heat. However, the net effect during typical operation, particularly under high power demands, is usually exothermic.

2.3. Auxiliary Systems and Environmental Factors

While not strictly generated *by* the battery, external factors and auxiliary components can also influence the battery’s thermal state:

- Ambient Temperature: Operating a hybrid vehicle in a hot climate (e.g., desert regions) means the battery starts at a higher baseline temperature, making cooling more challenging. Similarly, in cold climates, energy might be needed to warm the battery.

- Battery Management System (BMS) Components: The electronic components of the BMS, while low power, do generate a small amount of heat that contributes to the thermal load within the battery pack enclosure.

- Inefficiencies in Power Electronics: The inverters, converters, and chargers associated with the battery system also generate heat, some of which can radiate to the battery pack if not properly isolated.

Effective thermal management systems are designed to detect, dissipate, or add heat as needed, ensuring these various heat sources do not push the battery outside its optimal operating window.

3. Passive Thermal Management Strategies

Passive thermal management relies on inherent material properties and design principles to dissipate or retain heat without requiring external energy input for active components like pumps or fans. These methods are often simpler, more cost-effective, and lighter, making them attractive for smaller hybrid battery packs or those with lower power demands, typically found in mild hybrids.

3.1. Air Cooling (Natural and Forced Convection)

Air cooling is one of the most straightforward and common passive (or semi-passive) thermal management strategies, particularly in earlier HEVs and mild hybrids:

- Natural Convection: This involves designing the battery pack with vents or openings that allow ambient air to flow naturally over the battery cells. As the battery heats up, the warmer air rises and exits the pack, drawing in cooler air from below. This is highly dependent on vehicle speed and ambient temperature, offering limited control.

- Forced Air Cooling: In many modern HEVs, a small fan is used to actively draw air, often conditioned air from the passenger cabin, through the battery pack. While the fan is an active component, the primary cooling medium is air, and the system is still considered passive in comparison to liquid-based systems. Channels or ducts are designed within the battery pack to ensure uniform airflow around the cells. This method is effective for moderate heat loads but becomes less efficient as power demands and pack sizes increase. For instance, early Toyota Prius models largely relied on forced air cooling, drawing air from the cabin.

3.2. Heat Sinks and Thermal Interface Materials (TIMs)

These components are critical for efficient heat transfer from the battery cells to a cooling medium:

- Heat Sinks: Typically made of aluminum or copper, heat sinks feature fins or other geometries designed to maximize surface area. They are placed in direct contact with battery cells or modules to absorb heat and dissipate it into the surrounding air or into a cooling plate.

- Thermal Pads and Greases: To ensure efficient heat transfer between battery cells (which often have irregular surfaces) and heat sinks or cooling plates, thermal interface materials (TIMs) are used. These include thermally conductive pads, gap fillers, and greases that fill microscopic air gaps, which are poor conductors of heat, thereby significantly improving thermal contact and reducing thermal resistance.

3.3. Battery Module Design and Material Selection

The internal arrangement and materials of the battery pack itself play a crucial passive role:

- Cell Spacing and Arrangement: Designing adequate spacing between individual battery cells or modules allows for better airflow or contact with cooling elements. The orientation of cells can also be optimized to create natural convection pathways or to present a larger surface area to a forced airflow.

- Thermally Conductive Enclosures: The materials used for the battery pack casing can be selected not just for structural integrity and safety but also for their thermal properties. For instance, aluminum casings can help dissipate some heat to the ambient environment.

- Insulation: In cold climates, insulation materials can be strategically placed around the battery pack to retain heat generated during operation, helping the battery stay within its optimal temperature range without continuous active heating.

While passive methods offer simplicity, they often struggle with the higher heat loads generated by larger, more powerful battery packs found in modern PHEVs and full EVs. This is where active thermal management systems come into play.

4. Active Thermal Management Systems

Active thermal management systems go beyond passive heat dissipation by actively regulating the battery’s temperature through dedicated energy-consuming components. These systems offer far greater control, precision, and efficiency, making them essential for high-performance hybrid and electric vehicles, especially those with larger battery packs or fast-charging capabilities.

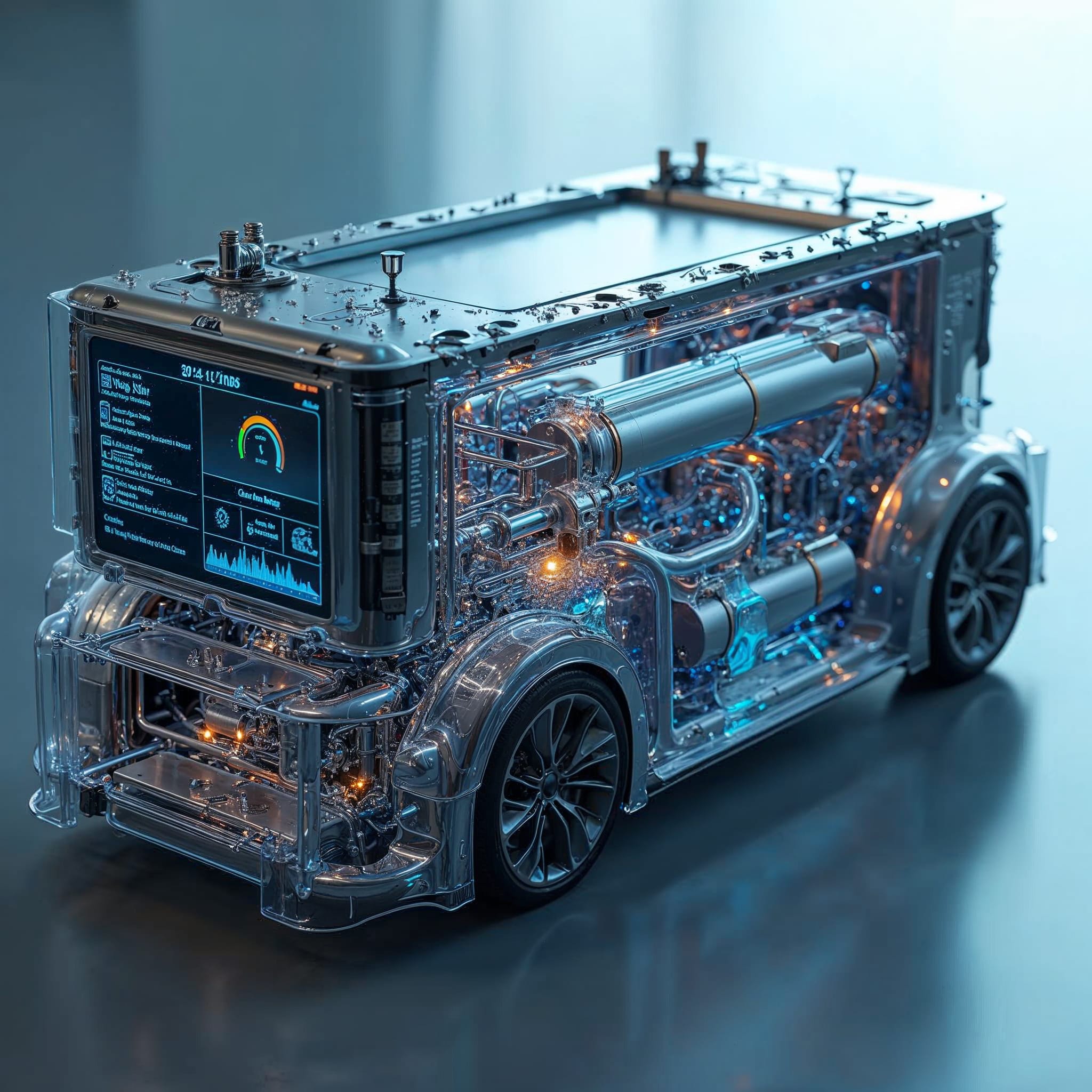

4.1. Liquid Cooling Systems

Liquid cooling is the most prevalent and effective active thermal management strategy in advanced HEVs and PHEVs due to its superior heat transfer capabilities compared to air:

- Cooling Plate / Cold Plate Design: These systems typically use a closed loop filled with a dielectric coolant, often a mixture of water and glycol (similar to engine coolant), or dedicated refrigerants. The coolant circulates through channels embedded within a cooling plate (also known as a cold plate) that is in direct contact with the battery cells or modules. Heat is transferred from the cells to the plate, then to the circulating coolant.

- Direct vs. Indirect Cooling:

- Indirect Cooling: This is the most common method. The coolant circulates through channels or plates that are thermally coupled to the battery cells but do not directly touch them. Heat is transferred via conduction through an interface material. This offers excellent insulation and safety against leaks.

- Direct Cooling (Immersive Cooling): A more advanced and less common approach where battery cells are directly submerged in a non-conductive, dielectric fluid. This provides highly efficient and uniform heat transfer across the entire surface of the cells. While promising for future high-power applications, challenges include fluid compatibility, leakage risks, and cost.

- Components: A typical liquid cooling loop includes a pump to circulate the coolant, a radiator to dissipate heat from the coolant to the ambient air (sometimes shared with the engine’s cooling system), and a chiller (often part of the vehicle’s AC system) to actively cool the fluid if needed.

4.2. Refrigerant-Based Cooling (Direct Expansion)

Some systems directly use the vehicle’s air conditioning refrigerant to cool the battery. This is known as direct expansion cooling:

- Evaporator Integration: A small evaporator unit from the vehicle’s AC system can be integrated directly into the battery pack or connected to a cold plate. As the liquid refrigerant evaporates within the evaporator, it absorbs a large amount of heat from the battery, providing very efficient cooling.

- Advantages: Can provide very rapid and powerful cooling, especially useful for PHEVs that experience higher thermal loads during spirited driving or fast charging. It leverages existing vehicle components, potentially reducing complexity in some aspects.

4.3. Thermo-Electric Coolers (TECs / Peltier Devices)

Thermo-electric coolers utilize the Peltier effect to create a temperature difference when an electric current is passed through two dissimilar conductors. They can both heat and cool without moving parts:

- Principle: When current flows, one side of the TEC becomes cold, and the other side becomes hot. By reversing the current, the hot and cold sides switch.

- Applications: While highly precise for temperature control, TECs are generally less efficient and more expensive for large-scale battery cooling compared to liquid systems. They are typically used in niche applications where precise temperature zones are needed or for smaller, localized cooling requirements, rather than for the entire main battery pack of a hybrid vehicle. Their high power consumption is a significant drawback for automotive applications.

4.4. Integrated HVAC Systems and Heat Pumps

Modern hybrid vehicles increasingly integrate battery thermal management with the cabin’s heating, ventilation, and air conditioning (HVAC) system:

- Shared Components: The vehicle’s main AC compressor and condenser can be used to cool the battery coolant. This efficient sharing of resources reduces weight and complexity.

- Heat Pumps: Advanced systems employ a heat pump, which can either move heat away from the battery to cool it, or move heat into the battery to warm it. Heat pumps are far more energy-efficient than resistive heaters for warming the battery in cold weather, as they ‘pump’ existing heat rather than generating it from scratch. This bi-directional capability is crucial for maintaining optimal battery temperatures in both hot and cold extremes, significantly boosting overall vehicle efficiency and battery lifespan.

The choice of active thermal management system depends on factors such as battery size, power output, target performance, cost constraints, and desired lifespan, with liquid cooling and heat pump integration representing the cutting edge for high-performance hybrids.

5. Advanced Thermal Management Technologies and Future Trends

As hybrid technology continues to evolve, so too do the methods for keeping batteries at their ideal temperature. Researchers and engineers are constantly exploring innovative solutions to enhance thermal efficiency, reduce system complexity, and improve overall battery performance and longevity.

5.1. Phase Change Materials (PCMs)

Phase Change Materials offer a semi-passive approach to thermal management, leveraging the latent heat absorbed or released during a phase transition (typically solid to liquid) at a specific temperature:

- Working Principle: When a battery generates heat, the PCM surrounding it absorbs this heat as it melts, undergoing a phase change without a significant rise in its own temperature. This process effectively “buffers” the battery’s temperature, keeping it within a stable range even during high power demands. Once the heat load subsides, the PCM solidifies, releasing the stored heat slowly.

- Advantages: PCMs are lightweight, require no active energy input once installed for cooling (though active cooling might be needed to re-solidify them for the next cycle), and can provide excellent thermal buffering.

- Challenges: PCMs have limited thermal conductivity in their solid state, can have issues with volume expansion during melting, and their thermal capacity is finite. Hybrid systems often combine PCMs with liquid cooling for optimal performance.

5.2. Nanofluids

Nanofluids are engineered coolants that contain suspended nanoparticles (e.g., copper, aluminum oxide, carbon nanotubes) within a base fluid (like water or glycol). These nanoparticles significantly enhance the thermal conductivity of the fluid:

- Enhanced Heat Transfer: The higher thermal conductivity of nanofluids allows them to absorb and transfer heat much more effectively than conventional coolants. This can lead to smaller and lighter cooling systems or provide superior cooling performance for existing systems.

- Potential Benefits: Improved battery temperature uniformity, better heat dissipation, and potentially faster charging and discharging rates without overheating.

- Research Status: While promising, nanofluids are still largely in the research and development phase for automotive applications due to challenges like long-term stability of nanoparticles, potential for clogging, and increased pumping power requirements.

5.3. Immersive Cooling (Direct Liquid Contact)

As mentioned briefly under active liquid cooling, immersive cooling involves directly submerging battery cells into a non-conductive, dielectric coolant fluid:

- Maximum Contact: This method offers the most intimate contact between the coolant and the cells, leading to exceptional heat transfer efficiency and highly uniform temperature distribution across the battery pack.

- Dielectric Fluids: Specific engineering fluids, such as mineral oils or synthetic esters, are used because they do not conduct electricity, ensuring safety and preventing short circuits.

- Future Potential: Immersive cooling is particularly attractive for ultra-fast charging scenarios and high-performance applications where heat generation is intense. It could also simplify battery pack design by eliminating complex cold plates and thermal interface materials. It is currently being explored for high-performance EVs and some specialized applications.

5.4. Smart Thermal Management and Predictive Algorithms

The future of thermal management is intelligent and predictive:

- AI and Machine Learning: Advanced algorithms can analyze driving patterns, environmental conditions, navigation data (e.g., upcoming hills or traffic), and battery degradation trends to predict future thermal loads.

- Optimized Control: Based on these predictions, the TMS can proactively adjust cooling or heating strategies, ensuring the battery is at its optimal temperature even before high demands are placed upon it. For example, a system might pre-cool the battery if a fast-charging stop is detected on the navigation route.

- Enhanced Efficiency: This predictive capability minimizes energy consumption by the TMS, as it only activates cooling or heating when truly necessary, or anticipates needs to run components at optimal efficiency.

These advanced technologies, often integrated with sophisticated Battery Management Systems (BMS), represent the next frontier in extending hybrid battery lifespan and unlocking even greater performance potential.

6. The Interplay of Battery Management System (BMS) and Thermal Management System (TMS)

The Battery Management System (BMS) is the brain of the battery pack, while the Thermal Management System (TMS) acts as its sophisticated climate control. These two systems are inextricably linked and function in a tightly integrated manner to ensure optimal battery operation, safety, and longevity. Without their seamless cooperation, a hybrid battery would quickly fail to meet performance expectations or, worse, become a safety hazard.

6.1. BMS: The Central Intelligence Unit

The BMS is a complex electronic system responsible for monitoring and controlling all critical aspects of the battery pack. Its primary functions include:

- Monitoring Parameters: Continuously measures individual cell voltages, total pack voltage, current flowing in and out of the battery, and crucially, multiple temperature points within the battery pack. High-quality systems will have sensors strategically placed to capture temperature variations across different modules and even within individual cells.

- State-of-Charge (SoC) and State-of-Health (SoH) Estimation: Calculates the remaining charge and assesses the overall health and degradation of the battery, often using temperature data as a key input for accurate estimation.

- Cell Balancing: Ensures that all cells within the pack are charged and discharged uniformly, preventing imbalances that can lead to premature degradation and heat generation in overloaded cells.

- Protection Features: Implements various safety measures such as over-charge protection, over-discharge protection, over-current protection, and perhaps most importantly in the context of thermal management, over-temperature and under-temperature protection. If temperatures exceed or fall below safe thresholds, the BMS will limit power, reduce charging current, or even shut down the battery to prevent damage or thermal runaway.

6.2. TMS: Executing the Thermal Strategy

The TMS comprises the physical components (fans, pumps, radiators, chillers, heaters, etc.) and their control logic that actively manage the battery’s temperature. It receives critical instructions and data from the BMS.

- Temperature Sensing and Data Relay: The BMS is equipped with an array of temperature sensors distributed throughout the battery pack. These sensors provide real-time temperature data to the BMS control unit. The placement of these sensors is critical; they are typically located in areas prone to heat generation or where temperature variations are expected.

- Control Algorithms: Based on the temperature data received from the sensors, along with other parameters like current draw, SoC, and ambient temperature, the BMS algorithms determine the appropriate action for the TMS. For example, if the battery temperature starts to rise during aggressive driving, the BMS will instruct the TMS to activate the liquid cooling pump and chiller. If it’s a cold morning, the BMS might activate a heater to bring the battery up to an optimal operating temperature before allowing full power or charging.

- Proactive vs. Reactive Control: Modern BMS-TMS integration aims for proactive control. Instead of merely reacting to rising temperatures, the system can anticipate thermal loads based on driving patterns, navigation data, and predicted power demands. This allows the TMS to pre-cool or pre-heat the battery, ensuring it’s always in its optimal temperature window, maximizing both performance and longevity.

- Fault Detection and Mitigation: The BMS is programmed to detect anomalies in temperature readings or the behavior of TMS components. If a cooling fan fails, a pump malfunctions, or a temperature sensor gives an erratic reading, the BMS will register a fault, potentially trigger a warning light on the dashboard, and implement protective measures (e.g., reducing power output) to prevent damage. In the critical event of a precursor to thermal runaway (e.g., rapid, uncontrolled temperature spike in a cell), the BMS is the last line of defense, potentially isolating the affected module or safely shutting down the entire system.

This symbiotic relationship between the BMS and TMS is fundamental to the reliability and success of hybrid battery technology. It ensures that the battery operates within its design limits, extending its life, maintaining performance, and guaranteeing the safety that consumers expect from their hybrid vehicles.

7. Real-World Applications and Industry Insights

Examining how different manufacturers implement thermal management provides valuable insight into the diverse engineering approaches and their impact on real-world performance and longevity. The evolution of thermal management in hybrid electric vehicles often mirrors the increasing demands placed on their batteries.

7.1. Toyota Prius: A Pioneer in Air Cooling

The Toyota Prius, a trailblazer in hybrid technology, initially relied heavily on forced air cooling for its nickel-metal hydride (NiMH) battery pack. In earlier generations, a dedicated fan would draw cabin air through ducts and over the battery modules, then expel it. This system was relatively simple, cost-effective, and sufficient for the lower power demands and smaller capacity of the NiMH batteries. However, drivers in extremely hot climates sometimes reported reduced battery performance or shorter lifespans due to the limitations of air cooling in high ambient temperatures and the potential for drawing already warm cabin air over the battery.

As the Prius evolved and moved towards lithium-ion batteries in some later models and its PHEV variants, Toyota began incorporating more sophisticated active liquid cooling for those specific battery packs, recognizing the higher power density and thermal sensitivity of lithium-ion technology. This transition highlights the industry’s continuous adaptation to new battery chemistries and performance requirements.

7.2. Hyundai Ioniq and Kona Electric: Embracing Liquid Cooling

Hyundai’s approach with its Ioniq Hybrid and PHEV models (and particularly its full EVs like the Kona Electric and Ioniq 5) showcases a robust commitment to liquid cooling. These vehicles utilize a closed-loop liquid cooling system, typically employing a glycol-water mixture, circulated by an electric pump through cooling plates integrated with the battery modules. This system often shares components with the vehicle’s HVAC system, allowing for efficient cooling or heating of the battery as needed. The benefit is clear: better temperature uniformity across the battery pack, enabling higher power output, faster charging rates (especially for PHEVs), and significantly improved battery longevity, even in challenging climates. This is a common and effective strategy for modern hybrid and electric platforms.

7.3. Honda Insight: A Balance of Air and Liquid

Honda’s hybrid offerings, such as the Insight, have historically leveraged air cooling for their smaller battery packs. However, as battery technology and consumer expectations have advanced, Honda has also evolved its thermal management strategies. For example, their more advanced hybrid powertrains and upcoming electrified vehicles often feature more intricate air-cooling designs or transition to liquid-cooled systems for their lithium-ion batteries. This shows a pragmatic approach, where the complexity of the TMS is matched to the specific battery chemistry, size, and performance profile of the vehicle, balancing cost, weight, and thermal performance.

7.4. Impact on Warranty, Consumer Experience, and Resale Value

Effective thermal management has tangible benefits:

- Extended Warranty Periods: Manufacturers confidently offer longer warranties (often 8-10 years or 100,000-150,000 miles) on hybrid battery packs with robust thermal management, as it directly contributes to their expected lifespan.

- Consistent Performance: Drivers experience consistent power delivery and regenerative braking efficiency regardless of ambient temperature or driving conditions. This leads to a more predictable and enjoyable driving experience.

- Higher Resale Value: Vehicles known for excellent battery longevity due to superior thermal management tend to retain higher resale values, as potential buyers are less concerned about costly battery replacements.

- Safety Assurance: The integration of advanced TMS with the BMS ensures that safety thresholds are never breached, providing peace of mind to vehicle owners.

The continuous improvement in thermal management systems is a testament to the industry’s dedication to making hybrid vehicles not just environmentally friendly, but also reliable, high-performing, and long-lasting members of the automotive landscape.

Comparison Tables

Table 1: Passive vs. Active Cooling Systems for Hybrid Batteries

| Feature | Passive Cooling (e.g., Air Cooling) | Active Cooling (e.g., Liquid Cooling, Heat Pump) |

|---|---|---|

| Mechanism | Relies on natural convection or forced air circulation by fans. | Uses circulating fluid (liquid or refrigerant) with pumps, radiators, chillers, or heaters. |

| Heat Transfer Efficiency | Moderate, less efficient for high heat loads. Air has lower thermal conductivity. | High, very efficient for high heat loads. Liquids have higher thermal conductivity. |

| Temperature Control Precision | Limited control, highly dependent on ambient conditions. | High precision, can maintain a narrow optimal temperature range. |

| Energy Consumption | Very low (only for fans in forced air systems). | Higher (pumps, compressors, heaters consume energy). |

| Complexity & Weight | Simpler, lighter. | More complex, heavier (additional components, fluid). |

| Cost | Generally lower initial cost. | Higher initial cost. |

| Typical Application | Mild hybrids, smaller battery packs, lower power demands, older HEVs. | PHEVs, full EVs, larger battery packs, high power demands, fast charging. |

| Impact on Lifespan/Performance | Sufficient for moderate use, but less optimal under extreme conditions; may limit lifespan/performance. | Significantly extends lifespan and optimizes performance across diverse conditions. |

Table 2: Impact of Temperature on Hybrid Battery Parameters

| Battery Parameter | Low Temperature (<0°C / 32°F) | Optimal Temperature (20-35°C / 68-95°F) | High Temperature (>40°C / 104°F) |

|---|---|---|---|

| Usable Capacity | Reduced significantly due to sluggish ion movement. | Maximized, full capacity available. | Gradual permanent degradation (capacity fade). |

| Power Output | Significantly reduced; sluggish acceleration, weak regen braking. | Maximized, peak performance. | Reduced due to increased internal resistance; power fade. |

| Charging Speed | Slowed down, often limited by BMS to prevent lithium plating. | Fastest and most efficient charging. | Can cause rapid degradation during fast charging; limited by BMS. |

| Lifespan/Degradation | Potential for lithium plating (irreversible damage) if charged too fast. | Longest lifespan, minimal degradation rate. | Accelerated degradation, permanent capacity loss, shorter lifespan. |

| Internal Resistance | Increased significantly due to electrolyte viscosity and slow kinetics. | Minimal, stable. | Increases, leading to more heat generation and lower efficiency. |

| Safety Risk | Lower immediate risk, but potential for dendrite formation during cold charging. | Lowest risk, stable electrochemical reactions. | Increased risk of thermal runaway in extreme cases due to exothermic side reactions. |

| Efficiency | Lower overall energy efficiency due to resistive losses and limited power. | Highest energy efficiency. | Lower overall energy efficiency due to resistive losses and energy spent on cooling. |

Practical Examples and Scenarios

To truly grasp the importance of thermal management, let’s consider a few real-world scenarios and how effective or ineffective thermal control plays out for a hybrid vehicle owner.

Scenario 1: The Mountain Commute in Summer

Consider a driver in Arizona taking their hybrid SUV on a daily commute that involves significant uphill driving at highway speeds, followed by a steep descent. The ambient temperature can easily hit 40°C (104°F) or higher.

- Uphill Climb: During the climb, the hybrid battery works hard, constantly discharging to assist the engine, especially during accelerations. This high current draw generates a considerable amount of heat within the battery cells. A robust liquid cooling system (common in modern PHEVs and larger HEVs) will immediately detect the rising temperatures via its BMS. The system will activate pumps and direct coolant through the battery’s cold plates, dissipating the heat to a radiator and possibly engaging the vehicle’s AC chiller to further cool the liquid. This ensures the battery stays within its optimal range, preventing power fade and maintaining consistent assistance to the engine. Without this, the driver would likely experience reduced acceleration, a noticeable drop in performance, and accelerated battery degradation over time.

- Steep Descent: On the way down, the regenerative braking system will be heavily engaged, recapturing kinetic energy and rapidly recharging the battery. This rapid charging also generates heat. Again, the active TMS is crucial. It continues to manage the temperature, preventing overheating from regenerative energy influx. In a passively cooled hybrid, repeated steep descents and regenerative braking in hot weather could quickly overwhelm the system, potentially forcing the BMS to limit regenerative braking (reducing efficiency) or to even engage friction brakes more often, leading to increased wear and reduced fuel economy.

Scenario 2: Winter Mornings and Fast Charging

Imagine a driver in Minnesota owning a plug-in hybrid electric vehicle (PHEV) who plugs it in every night. Overnight temperatures can drop to -15°C (5°F).

- Cold Start and Driving: In the morning, if the battery is liquid-cooled with an integrated heat pump, the TMS can pre-heat the battery pack. The heat pump efficiently draws warmth from the ambient air (or other sources) and transfers it to the battery coolant, bringing the battery up to an optimal operating temperature before the drive even begins. This means the driver experiences immediate full power for electric-only driving, efficient regenerative braking, and no restrictions on initial acceleration. In contrast, a battery without active heating would start very cold, leading to sluggish electric performance, reduced range, and potentially limited regenerative braking, all of which negatively impact fuel efficiency and driving experience.

- Public Fast Charging: If the driver needs to use a public fast charger on a cold day, a heated battery is critical. The BMS will only allow fast charging if the battery is warm enough to prevent lithium plating. A PHEV with a sophisticated TMS and heat pump can quickly warm itself, allowing for maximum charging speed. A cold battery without active heating would either refuse fast charging or charge at a significantly reduced rate, turning a quick stop into a prolonged wait.

Scenario 3: Prolonged Traffic Jams in Hot Climates

A hybrid taxi operating in a dense, hot urban environment like Bangkok, stuck in bumper-to-bumper traffic for hours.

- Idling and Low Speed: In this scenario, the vehicle’s speed is low, limiting natural airflow for passive cooling. The battery is constantly cycling, powering the vehicle at low speeds, assisting with frequent stop-starts, and capturing small amounts of regenerative energy. All this activity generates heat. An effective TMS will be continuously working in the background. If it’s a forced air system, the fan will be drawing air, potentially cabin air that’s already warm. If it’s a liquid-cooled system, the pumps and possibly the chiller will be engaged. The system is preventing the battery from “soaking” in heat and ensuring it remains ready for the next burst of acceleration. Without adequate cooling, the battery temperature would steadily climb, leading to performance limitations, higher fan noise (if air-cooled), and long-term degradation.

These examples underscore that thermal management is not just about extreme conditions, but about ensuring consistent, reliable performance and longevity across the entire spectrum of real-world driving scenarios. It’s the silent guardian of your hybrid battery.

Frequently Asked Questions

Q: Why is thermal management so important for hybrid batteries?

A: Thermal management is crucial because hybrid batteries, primarily lithium-ion, are highly sensitive to temperature extremes. Operating outside an optimal temperature range (typically 20-35°C) can severely impact their performance, lifespan, and safety. High temperatures accelerate chemical degradation, leading to capacity loss and potentially thermal runaway, while low temperatures reduce power output, usable capacity, and can cause irreversible damage during charging.

Q: What is the ideal operating temperature for a hybrid battery?

A: The ideal operating temperature for most lithium-ion hybrid batteries is generally considered to be in the range of 20°C to 35°C (68°F to 95°F). Within this range, the internal chemical reactions are most efficient, minimizing degradation and maximizing power output, usable capacity, and charging efficiency. Operating too far above or below this range will lead to detrimental effects.

Q: How do extreme temperatures affect battery lifespan?

A: Extreme temperatures significantly reduce battery lifespan. High temperatures (above 40°C) accelerate parasitic side reactions within the battery, leading to permanent capacity fade, increased internal resistance, and structural degradation. This is a primary driver of battery aging. Low temperatures (below 0°C) can cause lithium plating on the anode during charging, which is irreversible and severely damages the battery, permanently reducing its capacity and safety. Effective thermal management directly translates to a longer, healthier battery life.

Q: What are the main types of thermal management systems used in hybrids?

A: There are two main categories: passive and active systems. Passive systems, like forced air cooling (using fans to circulate air) or heat sinks, rely on natural heat dissipation. Active systems, which are more common in modern hybrids and PHEVs, use circulating liquids (e.g., glycol-water mixtures) or refrigerants through cold plates, often employing pumps, radiators, and chillers (part of the AC system) or heat pumps to precisely control temperature.

Q: Can I improve my hybrid’s battery thermal management?

A: As an owner, your direct influence on the sophisticated, integrated thermal management system is limited. However, you can indirectly help by avoiding consistently parking in direct sunlight in hot climates, especially when the vehicle is off, or pre-conditioning the cabin before driving. For PHEVs, utilizing pre-conditioning features while plugged in can also warm or cool the battery without drawing power from the battery itself. Regular vehicle maintenance, including ensuring air filters (for air-cooled batteries) and coolant levels (for liquid-cooled systems) are adequate, is also important.

Q: What role does the Battery Management System (BMS) play in thermal management?

A: The Battery Management System (BMS) is the brain of the battery pack. It continuously monitors individual cell voltages, current, and crucially, multiple temperature points. Based on this real-time data and sophisticated algorithms, the BMS sends instructions to the Thermal Management System (TMS) to activate cooling (fans, pumps, chillers) or heating (heaters, heat pumps) as needed. It also implements safety protocols, such as limiting power or charging if temperatures become unsafe, preventing damage or thermal runaway.

Q: Are all hybrid batteries cooled the same way?

A: No, cooling strategies vary significantly depending on the battery chemistry (e.g., NiMH vs. Li-ion), battery pack size, vehicle performance requirements, and cost considerations. Older or mild hybrids often use simpler forced air cooling, while newer, more powerful PHEVs and full EVs predominantly utilize advanced liquid cooling systems, sometimes integrated with the vehicle’s HVAC and heat pump for bi-directional temperature control.

Q: What are Phase Change Materials (PCMs) in this context?

A: Phase Change Materials (PCMs) are advanced materials that absorb and release large amounts of latent heat during a phase transition, typically from solid to liquid, at a specific temperature. In battery thermal management, PCMs are integrated around battery cells to absorb excess heat as they melt, acting as a thermal buffer to keep the battery within its optimal temperature range during high-power operations. They offer a semi-passive approach to help regulate temperature without continuous energy input for cooling.

Q: How do hybrid vehicle manufacturers test thermal management?

A: Manufacturers conduct extensive testing in highly controlled environments and real-world conditions. This includes driving vehicles in extreme hot and cold chambers, on dynamometers simulating various driving cycles, and in diverse geographic locations (e.g., deserts, arctic regions). They monitor hundreds of data points, including battery cell temperatures, coolant temperatures, system pressures, and component performance, to validate the effectiveness, reliability, and safety of the thermal management system under all foreseeable operating conditions.

Q: What are the future trends in hybrid battery thermal management?

A: Future trends include more intelligent, predictive thermal management systems using AI and machine learning to anticipate thermal loads based on driving patterns and navigation data. We’ll also see increased adoption of advanced materials like nanofluids for enhanced heat transfer, and further development of immersive (direct liquid contact) cooling for ultra-fast charging and high-performance applications. Heat pump integration for energy-efficient bi-directional temperature control will become even more widespread.

Key Takeaways

- Temperature is Paramount: Hybrid battery performance, lifespan, and safety are critically dependent on maintaining an optimal operating temperature, typically 20-35°C.

- Heat is the Primary Enemy: High temperatures accelerate battery degradation, leading to capacity fade, increased internal resistance, and pose a risk of thermal runaway.

- Cold is Also Detrimental: Low temperatures reduce power output, usable capacity, and can cause irreversible damage (lithium plating) if batteries are charged too quickly.

- Passive vs. Active Systems: Passive systems (e.g., air cooling) are simpler and lighter but less precise. Active systems (e.g., liquid cooling, heat pumps) offer superior control and efficiency, essential for modern, high-performance hybrids.

- BMS and TMS are Intertwined: The Battery Management System (BMS) acts as the brain, monitoring battery health and commanding the Thermal Management System (TMS) to implement heating or cooling strategies.

- Advanced Technologies are Emerging: Phase Change Materials (PCMs), nanofluids, and immersive cooling represent the cutting edge, offering enhanced thermal buffering and heat transfer capabilities.

- Smart Systems are the Future: Predictive algorithms and AI are enabling more proactive and energy-efficient thermal management, anticipating demands rather than just reacting.

- Real-World Impact: Effective thermal management translates directly into longer battery warranties, consistent vehicle performance in diverse climates, higher resale values, and enhanced safety for hybrid vehicle owners.

Conclusion

The journey through the intricate world of hybrid battery thermal management reveals a fundamental truth: the longevity and performance of our hybrid electric vehicles are not solely dependent on the battery’s chemistry, but profoundly on the engineering brilliance dedicated to controlling its thermal environment. From the foundational principles of heat generation to the sophisticated dance between the Battery Management System and its thermal counterpart, every aspect is meticulously designed to extend the life and enhance the capabilities of these essential power sources.

As hybrid technology continues its rapid evolution, pushing boundaries in power, efficiency, and charging speeds, the role of thermal management will only grow in importance. The seamless integration of passive and active cooling, the advent of smart, predictive systems, and the exploration of revolutionary materials like PCMs and nanofluids are all testament to an unwavering commitment to excellence. These ‘Thermal Management Secrets’ are not just technical marvels; they are the unseen guardians that ensure your hybrid vehicle delivers consistent performance, reliability, and ultimately, a greener, more sustainable driving experience for many years to come. Understanding these innovations helps us appreciate the true depth of engineering that powers the quiet revolution on our roads.